Experience and recorded data confirm that huge amounts of wasted energy are lost due to aging, and poorly maintained, or designed compressed air distribution network systems. This document has been prepared to assist you with the design, refurbishment, and modernization of your compressed air distribution systems.

To begin with we should establish the volume of compressed air, (cfm) that you plan to flow through the pipes. Consideration should be given to maximizing energy efficiency, the material that the pipe will be made of, system pressure drop, and compressed air quality.

Let’s break that down into smaller bite size pieces.

Piping layouts

The layout, and shape of your plant will significantly influence the configuration and type of compressed air piping you choose. The location of the compressor room is an important consideration, as this will impact the total distance that the air will travel inside the pipe, in order to reach the furthest take off point, also referred to as points of use, or ‘drops.’

We suggest that you sketch the layout of your space and shop areas, including the location of the air compressor generating station, and the points of use that will require compressed air. This sketch will assist you with visualizing what your system would look like, once it is installed, while helping you calculate the total linear footage of the distribution pipe work. Armed with this information you can easily confirm the necessary pipe size, and diameter, bracket locations, pipe and fitting quantities, valve arrangement, and system configuration.

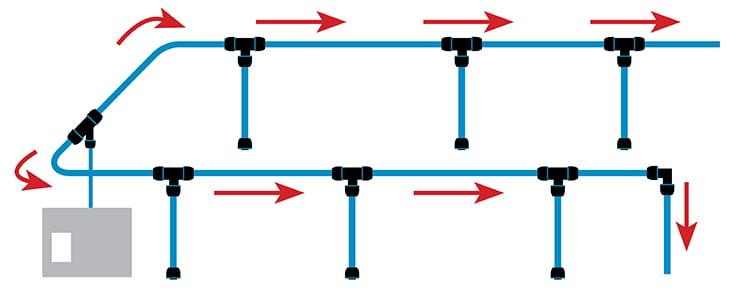

The two most common pipe work configurations, in manufacturing and production facilities, are the closed loop system, and the linear system.

Closed loop systems

Often referred to as a ring main, they are considered to be the most efficient configuration, but require more pipe, fittings, and labour to create and install them. The benefits of a closed loop system far outweigh the additional expense, as the loop/ring promotes equal, and uniformed system pressure from generation to point of use - with a balanced and equal flow of PSI pressure and CFM volume for all users. No one is starved of pressure.

Linear pipe system

This is a great alternative when a closed-loop configuration is not possible. In a perfect world, the compressor station would be ideally located in the centre of the linear network. This allows air to flow in both directions from the compressor to the furthest ‘drop’, or point of use. Another option is to install more than one compressor, however they may struggle to operate in harmony, as they battle for the lead position in the system pressure pecking order.

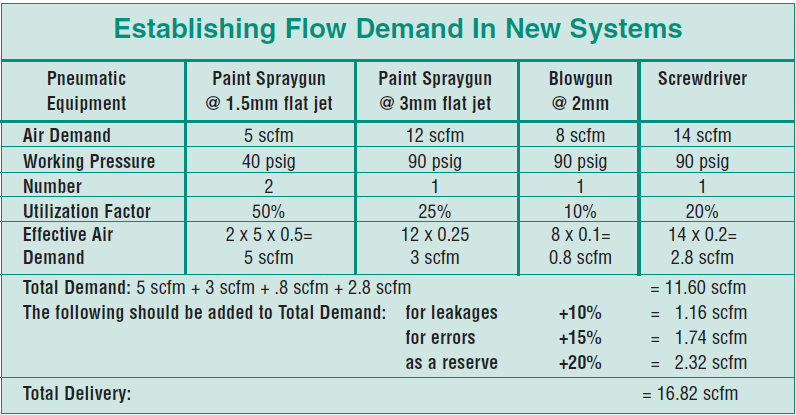

Point of use compressed air consumption

The table below is a helpful guide to establish the average consumption of compressed air volume by spray paint guns, air tools and nozzle blow offs. Bear in mind that the aforementioned items rarely “fire”, or function at the same time, so adding all of their CFM values together will provide you with a worst case scenario.

Correctly sizing, and installing air receiver tanks will create ample reservoir storage to mitigate pressure loss, and avoid rapid loading of the air compressors should multiple consumption occur simultaneously at point of use. The demand will be supplied from stored energy, as opposed to directly taxing the compressors.

Air receiver storage tanks and reservoirs

Wisely investing in, and selecting suitably sized air receiver storage tanks will pay dividends in the long run.

✓ Applying for, and gaining incentives, in Ontario, to fund your adding and increasing of storage vessels is easy to access, and available.

✓ The “rule of thumb” for selecting storage tank capacity should begin with a minimum of 3 gallons of storage for every 1 cfm @ 100 psig generated.

✓ In essence you can never have too much storage.

✓ Tanks require little or no maintenance, but provide many benefits, including, but not limited to:

- Reducing rapid loading of the air compressor, which in turn extends the service life expectancy of the compressor control and inlet valve assemblies.

- Energy saving, as the compressor will run unloaded, rest, or stop, while the plant draws from the stored compressed air energy reservoirs. Some compressors' energy consumption will be reduced, by as much as 40%, when operating unloaded, compared to when they are loaded and compressing air.

- Air receivers allow the compressed air to expand, reduce its velocity, while assuming a cyclonic motion. These changes encourage the cooling and state of the air to condense liquid, and reduce temperature. Subsequently, the clean air treatment, filters and air dryers downstream receive a reduced load of water and oil contamination, and preferred approach temperatures. Ensure that your receiver tanks are equipped with an energy savvy automatic condensate drain trap

Save on Energy incentives are also available to encourage you to invest in energy saving automatic drain traps, and eliminate, or avoid adding energy wasteful timed solenoid style drains to the “grid”

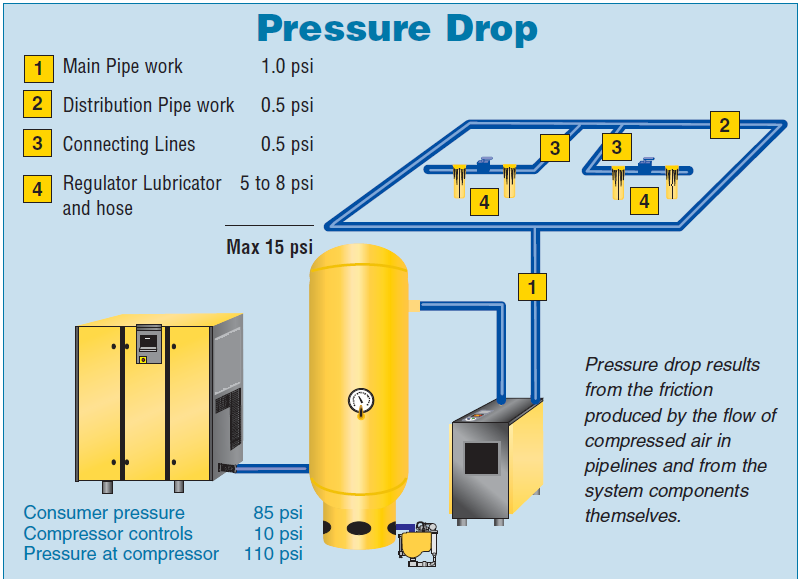

CFM pipe work volume

Selecting the correct size of compressed air pipe work is vitally important in providing adequate CFM volume flow, and stable system pressure to all of your points of use. The pipe diameters you install will dramatically impact system pressure drop, and available volume at point of use. Poor choices in pipe materials, diameter, and layout cause flow restrictions, which often result in significant pressure drop. Pressure drop is a leading cause of increased energy consumption, disgruntled end users, poor performance of cylinders, valves, air driven tools and equipment.

Based on a Blue Aluminum Pipe - Kaeser SmartPipe+, “closed loop” network system, this guide indicates the suggested pipe diameter for flow of compressed air volume, and the linear feet of the pipe system.

Wasted energy

An estimated 15% of the total compressed air generated in a typical manufacturing or production facility is lost to leaks. That’s a staggering waste of money and Hydro energy. To provide context, a 100hp (75kW) rotary screw air compressor operating 2 shifts, 5 and a half days a week, with Hydro costs of $0.13c per kW/hr. would rack up a Hydro bill of approximately $44,616 per year.

In this example, compressed air leaks are responsible for $6,692 of this Hydro bill.

Needless to say, leak detection is a low hanging fruit to pick, and essential to the reduction of the cost of compressing air. The ROI from identifying compressed air system leaks, and following up with repairing them, is rewarding, and rapid.

Compressed Air Pipe Material Choices

Now that we have our cfm flow, and pipe diameter established, let's dive into compressed air pipe material choices.

This is not an area you should take for granted, or look to cut corners, as pipes and fittings are an integral part of a compressed air system running trouble free and efficiently. If the quality of these components is incorrectly spec’d, quality is poor, or the installation is careless, the results can be dangerous and very costly for years to come.

Most compressed air pipe systems are constructed with metal piping. Metal pipes are the preferred choice for most compressed air systems. Below are some options for metal piping material:

- Black Steel Pipe - Black steel is the least expensive, and most commonly used compressed air pipe material. Black steel is strong and durable, but arrives on site partially corroded, before it's hung. The screwing and threading process is time consuming and cumbersome, and subject to slippage and leaks. It is heavy and adds additional roof loading to the building's structure, especially when large diameter pipe and long runs are installed. Because the material is black, it is very difficult to identify as compressed air piping, amongst all of the other pipes, in the roof space when looking up from the ground.

- Galvanized Steel Pipe - Galvanized steel is extensively used in compressed air piping networks. It is less susceptible to corrosion than Black pipe, however the galvanized coating can flake off, particularly when the pipe is subjected to high temperatures. This unwanted corrosion can block orifices, filter elements, and cause other pneumatic equipment failures. Again, the roof loading and building structure are impacted by the weight of the pipe, and identifying the pipe is once again difficult from a far amongst other piping.

- Copper Pipe - Copper pipe is the chosen material in clean rooms and hospitals, to name a few critical applications. Degreased Copper is synonymous with oil free compressed air applications. Copper is expensive and desirable, so installation costs and theft are typically higher than most other pipe materials. Copper pipes won’t corrode and are easy to cut, braze, or weld. Utilizing special fittings, and tools means that Copper pipes can be press fitted together, eliminating specialized installation labour forces. The smooth internal surface, and lightweight property of copper results in easy installation, minimal weight loading of roof structures, with excellent flow rate, and friction loss characteristics.

- Blue Aluminum Pipe Kaeser SmartPipe+ - The majority of pipe installations we install today use Blue Aluminum SmartPipe+. This product is powder coated Blue, straight out of the box, so it's easily identified in the ceiling space as a compressed air pipe. The Aluminum never corrodes internally or externally, under normal circumstances, so flow and integrity are infinite.

SmartPipe+ is as light as a feather, so there is no major weight load added to the roof structure, and the pipes can even be bent on a pipe bender to avoid obstructions, such as electrical conduits. Bending the pipe negates the need for additional fittings, as these create unwanted pressure drops, additional fitting and labour costs.

Should you choose to relocate a pipe run, or move your entire operation elsewhere, SmartPipe+ can be disassembled and everything can be repurposed in a new location.

Installation is completed in half the time of traditional material piping, and a 20 foot length of 2” Blue aluminum pipe can be lifted in one hand. The pressure rating and CRN approval of SmartPipe+ makes this product ideal for high quality compressed air systems.

- Stainless Steel Pipe - Stainless steel pipe is the chosen material in food and pharmaceutical applications because the internal and external surfaces have zero risk of corroding. Stainless steel is ideal in critical applications.

Because Stainless steel pipe and fittings are expensive, it is rarely used in “standard” compressed air pipe installation systems. Installation is fairly simplistic, as Stainless steel can be welded, or pressed, depending on system specifications. A potential “strike” against Stainless steel is its weight. When wall thickness schedules of Stainless materials increase, pipes and fittings can be heavy, and subsequently, it is difficult to install, and adds a load burden to the building's structures.

Compressed air quality

Oil injected/flooded industrial rotary screw and reciprocating piston compressors will undoubtedly create oil, particular, and water contamination. This unwanted carryover causes pipework corrosion, equipment failures, promotes bacterial growth, and production spoilage.

During the design and selection process for your compressed air distribution pipework system, consider what level of compressed air quality for each point of use and application. Some drops may require a filter regulator lubricator (FRL) set, a sterile compressed air arrangement, specific pressure dewpoint, or dictating a variation of air dryer at point of use such as refrigerated or desiccant types.

A useful guide to assist you with selection is the ISO 8573.1 2010 compressed air quality class. This quality guideline is a standard that is recognized across the globe to level the playing field for everyone. Selecting the appropriate “clean air treatment” equipment, (dryers and filters), will depend on the specification you require, and the ISO quality class will assist your selection process.

Final considerations, checks and balances should include:

- Future expansion plans. Install plenty of shut off valves. In a ring main or loop system, and why not add a valve in each corner of the ring? This enables sectional shut off, without losing compressed air throughout your facility, should additional drops, or modifications be required.

- Select the best and correct pipe materials.

- Validate that the pipe and fittings are CRN approved and have CRN numbers on it.

- Avoid under-sizing pipe diameters in an attempt to save money. The compressor motor energy exerted to overcome the piping pressure drop will far exceed any cost cutting savings, at the front end, in the long run.

- Ensure your installer has TSSA approval. TSSA has the authority, and power to shut your system down if it is installed without the correct TSSA certification, testing and CRN documents in place.

- Create a pipe loop, or ring main, to ensure that all of the users and points of use receive equal and stable pressure, wherever they are located in the pipe network.

- Remember to choose your clean air treatment wisely. Heatless desiccant dryers consume 15% of their throughput volume, making them an expensive luxury to own and operate. Filter manufacturers state their oil ppm carryover, and particulate retention rates, but ensure they quantify the % efficiency of their retention ability. Element efficiency can differ from one manufacturer to another by >100 times.

- Fix leaks on a regular basis.

- Fridge dryers are rated to operate in ambient, and approach temperatures of 100°C, at 100psig. Use this correction factor table if your site conditions vary. This will avoid under-sizing a fridge dryer.

- Ensure that compressed air take-offs and point of use drops are configured in a “Gooseneck” arrangement, to protect downstream equipment against water and oil contamination.

Key considerations for efficient compressed air systems

In conclusion, the efficient design, maintenance, and modernization of compressed air distribution systems are essential to maximize energy savings and productivity in manufacturing and production facilities. By carefully considering factors such as the volume of compressed air, piping layouts, material choices, and air quality, you can significantly reduce wasted energy and operational costs. Leak detection and repair offer a quick return on investment, and selecting the right pipe material, like Blue Aluminum SmartPipe+, can streamline installation and ensure long-term reliability. Additionally, maintaining high-quality compressed air at various points of use is critical, and adherence to ISO 8573.1 standards can guide your decision-making process. To achieve the best results, remember to plan for future expansion, use shut-off valves strategically, and avoid under-sizing pipe diameters. Finally, prioritize TSSA approval, and regularly address leaks while configuring take-offs and point-of-use drops in a way that safeguards downstream equipment. With these considerations in mind, you can enhance the efficiency and sustainability of your compressed air distribution system while reducing energy wastage and operating costs.

A well-planned distribution network can significantly impact your energy bills and overall productivity. To get started on enhancing your compressed air system and ensuring it operates at peak efficiency, contact Air Solutions Canada today. Our experts are ready to assist you in every step of the process, from system design and material selection to installation and ongoing maintenance. Don't let wasted energy drain your resources – take action now and make your compressed air system work for you. Contact us for a consultation and see the difference in your energy efficiency and cost savings.