When working to extract these precious minerals and natural resources, as well as maintain safety for work crews, mining companies rely on durable, energy-efficient and safe mining equipment. Compressed air is an important source of power in nearly all mining operations. Mining companies often rely on industrial compressed air systems or portable air compressors for electric and tools such as pneumatic loaders. Their efficiency, durability, safety, and ease of use make them ideal choices for many applications from mining to refining. Typical mining applications requiring compressed air include exploration drilling, instrumentation, agitation, smelting, refining, powering pneumatic tools, proper ventilation systems, drilling, and blasting.

Compressed Air Purity

Because oil and water can cause damage to equipment, it’s important that the compressed air you’re using is of high quality and high purity. To prevent as much contamination as possible it’s recommended to install a good filtration system and maintain regular upkeep of all equipment in your air compressor station. Our extensive range of clean air treatment products, such as filters dryers and oil/water condensate management, allow us to provide you with any level of ISO 8573.1 compressed air quality class. Air Solutions Canada Inc. preventative maintenance plans and best practices allow you to maintain your equipment and ensure it’s working efficiently. Some might say that it is impossible to associate the price of compressed air downtime with the cost of maintaining the equipment correctly. Our service division provides peace of mind for any facet of your compressed air generating station and its distribution network and accessories.

Mining Air Compressor Systems

Because mines are located in some of the most remote locations in the world, the equipment used is subject to harsh environments and continual operation. Unexpected downtime from equipment failure is extremely costly and inconvenient. Selecting the appropriate compressed air system is critical for your operations, impacting not only operational efficiency, but also the safety of your staff, and quality of your products. Air Solutions Canada Inc. is here to assist you in navigating this selection process, offering an extensive portfolio of products and services specifically designed for the underground mining industry. From energy-efficient compressed air to sophisticated clean air treatment, we provide the necessary tools to maintain a reliable and safe compressed air supply. We help you optimize your mining process to minimize, your environmental footprint. This also increases and sustains the uptime and efficiency of your mining operation.

Related products

Blowers

Kaeser blowers are built for a lifetime of high performance, low energy costs, and best in class performance, with flow rates between 170 ICFM and 2603 ICFM.

Vacuums

Kaeser's Rotary screw vacuum packages are the perfect solution to industrial Vacuum applications. Featuring our award-winning Sigma Profile™ airend. Our range of machines produce 166 to 551 acfm.

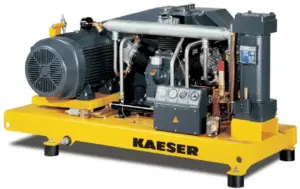

Boosters

When compressed air or gas applications require higher pressure than a “standard” air compressor can produce, high pressure booster compressors are an economical and effective solution.

Controllers

Kaeser's Sigma air Manager, SAM 4.0 provides complete system management for air compressors, blowers and vacuums, from a large easy to read screen, with remote access options.

Accessories

Whatever it is you're looking for, our accessories range from the gauges and valves in the compressor room, all the way through to the hoses, air knives, nozzles, and blow guns at the points of use.

Compressors

Our range of air compressors includes reciprocating piston, oil free, and oil injected rotary screw air compressors, from 3hp up to 700hp, and everything in between. If you do not know what you are looking for, we can assist with that too.

Dryers

Selecting the right dryer and filtration to ensure your facility receives clean, dry compressed air consistently, depends on many things. Our clean air selection process is based around ISO 8573.1 quality class standards.

Filters

If you are looking for assistance in the filtration of dirt, oil, water, bacteria, hydrocarbons, oil odor or vapor, we have a filter, or an element to capture unwanted contaminants you need to stop. Compressed air, inert gases, liquids, ambient air, and water filtration is what we do best.

Tanks

Horizontal and Vertical air receiver storage tanks are available, with the most common sizes kept in stock at our Hamilton warehouse.

Condensate Management

Disposing of the compressed air oil/water condensate byproduct, created by your compressor station, carries big legal, and environmental responsibilities. The person knowingly discharging oil to drain, is responsible.

N2 and O2 Generators

Reliable Nitrogen Supply, Anytime, Anywhere – Peak i-Flow Nitrogen Generators: Uninterrupted 24/7 operation ensures a consistent, on-demand nitrogen gas flow for various applications, boasting flow rates of up to 11,845 SCFH and purity levels reaching up to 99.9995% (5 PPM).

Pipe Work

Our mechanical team is TSSA certified to perform all types of pipe work. Stainless steel, copper, aluminum, galvanized and black steel pipe are available for supply and installation. Our team also specializes in ductwork, machinery moving, and rigging applications.

The ultimate guide on rightsizing your compressed air system

Choosing the right compressed air system is crucial to minimize the total cost of ownership. How do you calculate the air demand in flow rate (CFM) and pressure (PSIG), what's the power requirement (V), and how does that translate in a compressed air system with one or more compressors (hp)?

Download our Comprehensive Guide for Choosing the Right Compressor Size!

Why work with Air Solutions Canada

Working with the largest compressed air team in Southern Ontario has many benefits

Fastest emergency service

We guarantee a same day visit with dedicated emergency service technicians, on call 24/7. Every vehicle is equipped with a breakdown “crash kit” so in most cases we solve your problem immediately. Our 1st time fix rate is currently 93%.

Largest equipment inventory

We can quickly address all your compressed air needs and solve any emergency with over $2M of inventory, including an extensive “ready to go”, fleet of electric and diesel-driven compressors, spare parts and filters for most compressor brands.

Technicians dedicated to you

You have a dedicated primary and secondary technician at your disposal. They have all your equipment information and service history at their fingertips to ensure fast, familiar service and personalized support for every visit.

Competitive Pricing

We get preferential pricing and pass discounts on to our customers. We make reliable compressed air service affordable and easy to budget with flexible payment terms and various lease, rent and PAYG options.

Which type of air compressor is used in mining?

The most commonly used air compressors in mining are rotary screw air compressors and reciprocating piston air compressors. Rotary screw compressors are favored for continuous use due to their durability and ability to supply a steady flow of compressed air, while reciprocating piston compressors are often used for intermittent or small-scale operations. These compressors are essential for powering pneumatic tools, drilling, and ventilation systems in mines.

What is compressed air in mining?

Compressed air in mining refers to air that has been pressurized to drive various equipment and tools used in mining operations. It powers pneumatic drills, hammers, conveyors, and other machinery. Compressed air is also essential for ventilation in underground mines, providing breathable air and removing harmful gases or dust from the environment.

How does compressor mining work?

Compressor mining involves the use of compressed air to power equipment such as pneumatic drills, loaders, and transport systems. The air compressor generates pressurized air, which is then channeled to machinery via hoses or piping. This compressed air provides the force needed to operate various mining tools, ensuring efficiency and safety in operations, especially in hard rock drilling and tunneling.

What is air blasting in mining?

Air blasting in mining refers to the use of compressed air to clean surfaces, remove debris, or blast loose material. It is commonly used for clearing dust and dirt from mining equipment, or for surface cleaning before new phases of mining operations begin. In some cases, air blasting is also used for material removal in specific mining processes, such as cleaning ore or coal from rocks.