In ski and snowboard operations, dependable compressed air is the backbone of snowmaking cannons and a smooth guest experience. From feeding snow guns across the hill, to supporting lift operations and maintenance shops, your air system directly affects how much snow you can produce, how quickly you can open, and how reliably you can stay open through the season.

For many resorts, the compressed airstation, and the equipment within it, is one of the largest single energy users on the mountain. Industry studies estimate that the majority of snowmaking cost is tied to compressing air, which means even small improvements in system design, control, and leakage can have a disproportionate impact on operating expenses.

At Air Solutions Canada, we understand that every cold window counts. We help ski and snowboard resorts design, upgrade, and maintain compressed air systems that deliver consistent pressure, reliable flow, and real energy savings, so your team can focus on grooming reliable runs, not fighting aging compressors.

Compressed air for snowmaking and resort operations

In ski and snowboard resorts, compressed air is critical in several areas, including snowmaking lines and cannons, lift and control systems, maintenance shops, and support systems around the hill. Any instability in air pressure, quality, or supply can quickly translate into lost snowmaking windows, higher Hydro usage for less snow, added stress on equipment and piping, and unplanned downtime that puts opening dates and guest satisfaction at risk.

Our engineered systems focus on stable pressure, appropriate storage, and clean, dry air to protect your equipment and keep production predictable—especially during peak cold snaps when every gun is running.

Typical applications we support include:

- Air to snow guns and snowmaking lines across varied elevations

- Pneumatic systems in lift and control stations (where applicable)

- General plant air for shops, garages, and maintenance areas

- Cleaning, blow‑offs, and support processes around the hill

Tailored solutions for ski & snowboard resorts

Resorts face unique operating conditions: short, intense snowmaking seasons, wide temperature swings, and equipment that often runs overnight. Selecting the right compressed air system is critical for achieving reliable snow coverage and snow quality, lowering hydro costs, reducing your carbon footprint, and creating safer, quieter, less stressful working conditions for staff.

Air Solutions Canada supports resorts with a full range of compressed air services. We begin with an Air Demand Analysis (ADA) to pinpoint true CFM and pressure requirements across your hill. From there, we design snowmaking-ready rotary screw compressor stations sized for your operating conditions, supported by drying and filtration that keep moisture, oil, and particulates out of lines, guns, and valves. Intelligent controls then adjust output as demand changes, while our preventative maintenance and emergency service teams support you through the season with technicians who understand the pace and pressure of resort operations.

Energy efficiency and environmental impact are built into every discussion. When designing or retrofitting systems, we focus on practical ways to reduce kWh per cubic metre of snow through right-sized compressor capacity, improved staging and controls, leak reduction, and cleaner, more efficient snow gun operation, while supporting your broader sustainability goals.

When designing or upgrading a resort system, we consider key factors such as:

- Current and future snowmaking capacity targets

- Pressure stability at the farthest and highest guns

- Electrical and Hydro constraints, including peak demand

- Opportunities for heat recovery and controls integration

- Service access, redundancy, and ease of seasonal start‑up/shutdown

Working with us, you gain a partner who looks at the whole system. From a compressor house to the farthest gun on the hill, and one that helps you balance reliability, performance, and cost of ownership.

Proven experience on the hill

Our team has worked with private clubs and public resorts to solve common compressed air challenges. These often include aging piston compressors that are costly to maintain, unstable pressure that limits how many guns can run at once, systems that rely on cooling water, and stations that are loud, inefficient, and difficult to service during the season.

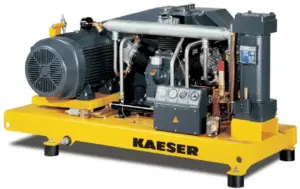

In one Ontario ski club project, we replaced legacy reciprocating compressors with a modern Kaeser rotary screw station, complete with integrated drying, high‑efficiency filtration, and a Sigma Air Manager 4.0 master controller to orchestrate load sharing, staging, and redundancy. The result was a quieter, more stable system that reduced maintenance demands, eliminated the need for cooling water, enabled heat recovery for space heating, reduced annual Hydro costs, and contributed to a payback in under a year, while increasing snowmaking capacity and improving snow quality feedback from members and guests.

You can read the full details and results in our Mansfield Ski Club case study.

Build a more reliable snowmaking season

When you partner with Air Solutions Canada Inc., you get more than new equipment. You gain a long‑term team focused on delivering reliable snowmaking capacity, lowering the total cost of ownership, reducing your carbon footprint, and creating a quieter, safer, more dependable operation for your staff and guests. Whether you are planning a full compressor house retrofit, looking to stabilize pressure and flow, or starting with an Air Demand Analysis to understand where the opportunities are, we can help you design a path to a more reliable snowmaking season.

Related products

Accessories

Whatever it is you're looking for, our accessories range from the gauges and valves in the compressor room, all the way through to the hoses, air knives, nozzles, and blow guns at the points of use.

Compressors

Our range of air compressors includes reciprocating piston, oil free, and oil injected rotary screw air compressors, from 3hp up to 700hp, and everything in between. If you do not know what you are looking for, we can assist with that too.

Dryers

Selecting the right dryer and filtration to ensure your facility receives clean, dry compressed air consistently, depends on many things. Our clean air selection process is based around ISO 8573.1 quality class standards.

Boosters

When compressed air or gas applications require higher pressure than a “standard” air compressor can produce, high pressure booster compressors are an economical and effective solution.

The ultimate guide on rightsizing your compressed air system

Choosing the right compressed air system is crucial to minimize the total cost of ownership. How do you calculate the air demand in flow rate (CFM) and pressure (PSIG), what's the power requirement (V), and how does that translate in a compressed air system with one or more compressors (hp)?

Download our Comprehensive Guide for Choosing the Right Compressor Size!

Why work with Air Solutions Canada

Working with the largest compressed air team in Southern Ontario has many benefits

Fastest emergency service

We guarantee a same day visit with dedicated emergency service technicians, on call 24/7. Every vehicle is equipped with a breakdown “crash kit” so in most cases we solve your problem immediately. Our 1st time fix rate is currently 93%.

Largest equipment inventory

We can quickly address all your compressed air needs and solve any emergency with over $2M of inventory, including an extensive “ready to go”, fleet of electric and diesel-driven compressors, spare parts and filters for most compressor brands.

Technicians dedicated to you

You have a dedicated primary and secondary technician at your disposal. They have all your equipment information and service history at their fingertips to ensure fast, familiar service and personalized support for every visit.

Competitive Pricing

We get preferential pricing and pass discounts on to our customers. We make reliable compressed air service affordable and easy to budget with flexible payment terms and various lease, rent and PAYG options.