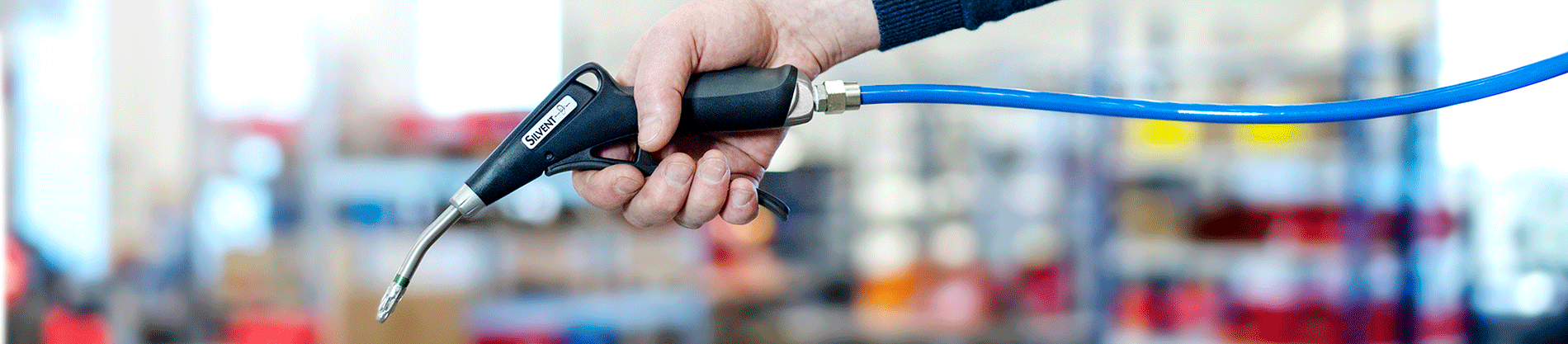

Air blow Guns

Blowing with compressed air poses serious risks if not handled properly, leading to injuries or fatalities. OSHA regulates air blow gun usage due to high static pressure risks when blocked, emphasizing a maximum pressure of 30 psi to prevent air embolisms. Compliance with OSHA standards ensures safer work environments. Silvent’s nozzle design,preventing complete blockage, further mitigates air embolism risks, prioritizing operator safety.

Did you find what you were looking for?

Compressed air safety – OSHA compliance

Silvent’s air blow guns fulfill OSHA requirements regarding blowing with compressed air. We can help you lower the sound level and minimize the risk of injuries associated with compressed air blowing. Silvent’s OSHA compliant air blow guns are quiet, safe and efficient. See our test against a regular air blow gun.

The system

Air blow guns are commonly utilized in various industries for tasks such as cleaning, drying, cooling, and removing debris from surfaces or machinery. They emit a controlled stream of compressed air, facilitating efficient and precise cleaning operations. Additionally, air blow guns can be employed to remove chips or swarf from machining operations, as well as to blow dust or particles from hard-to-reach areas. However, it's crucial to handle air blow guns with care and adhere to safety guidelines to prevent injuries, especially concerning the risk of high-pressure air entering the bloodstream, which can cause serious harm.

How it works

Our tried-and-tested approach to get you a reliable compressed air solution at the lowest possible cost of ownership looks like this:

Discovery call

Our solutions specialist visits your facility to discuss your current situation, pain points, future plans, and potential government incentives. We can undertake as little, or as much, of your project as you would like.

Requirement analysis

We analyze the compressed air equipment at your facility, its performance, condition, control mechanisms, and suitability. We ensure that storage, piping, and compressed air quality are in line with your requirements and best practices.

Turnkey design and installation

Everything we do is “in house.” Compressed air system design, air audits, leak detection, design, build, installation, and air compressor service are handled quickly and efficiently. This approach means that we manage every aspect of your project and create single source supply for you and your organization.

Maintenance and repair

Whether you require emergency breakdown response, predictive, or preventative maintenance our team has you covered. Air end and motor service and rebuilds, piping system, and analysation are also available.

Related products

Blowers

Kaeser blowers are built for a lifetime of high performance, low energy costs, and best in class performance, with flow rates between 170 ICFM and 2603 ICFM.

Accessories

Whatever it is you're looking for, our accessories range from the gauges and valves in the compressor room, all the way through to the hoses, air knives, nozzles, and blow guns at the points of use.

Compressors

Our range of air compressors includes reciprocating piston, oil free, and oil injected rotary screw air compressors, from 3hp up to 700hp, and everything in between. If you do not know what you are looking for, we can assist with that too.

Pipe Work

Our mechanical team is TSSA certified to perform all types of pipe work. Stainless steel, copper, aluminum, galvanized and black steel pipe are available for supply and installation. Our team also specializes in ductwork, machinery moving, and rigging applications.