Air Knives

Our air knives offer a superior alternative to open pipes, self-designed air knives, and air nozzles, particularly for applications requiring broad coverage. Developed to provide uniformly distributed coverage width and effective blowing force, our air knives are engineered by application specialists with extensive expertise in compressed air blowing. With a global presence in over 90 countries, our products enhance efficiency, reduce sound levels, and optimize compressed air usage. Our range includes standard options for various blowing distances and custom solutions like SILVENT 300™, tailored to meet specific application needs, ensuring maximum effectiveness and customer satisfaction.

Did you find what you were looking for?

Importance of air supply

To get the best performance from our air blow guns, air nozzles and air knives, it is important to choose the correct air supply size. If the supplying hose is too small, the product will not work properly, and the blowing force will not meet expectations. Here, we guide you through choosing the correct air supply for optimal product performance.

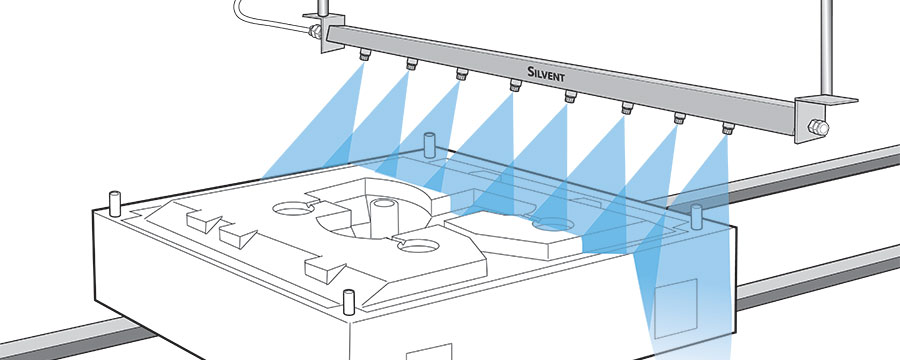

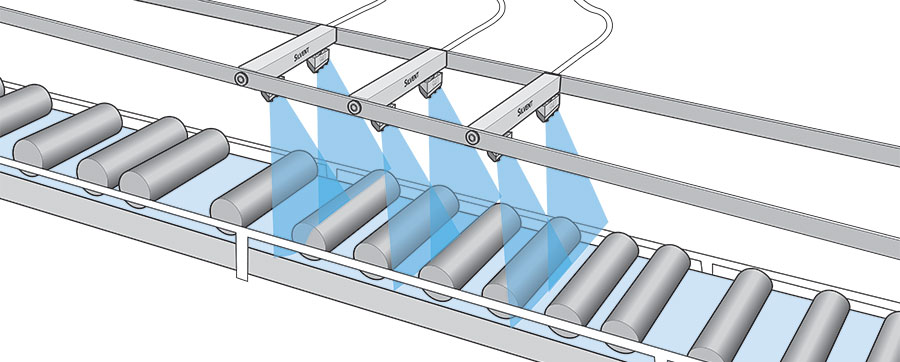

The system

Air knives are commonly used in industrial applications to efficiently blow away fluids, debris, and contaminants from surfaces or objects. They are typically mounted along conveyor belts or production lines, where they emit a high-velocity, controlled airstream to effectively remove unwanted materials. Additionally, air knives can be utilised to create an air curtain, serving as a barrier to prevent airborne contaminants or regulate temperature in specific environments such as cleanrooms or food processing facilities.

How it works

Our tried-and-tested approach to get you a reliable compressed air solution at the lowest possible cost of ownership looks like this:

Discovery call

Our solutions specialist visits your facility to discuss your current situation, pain points, future plans, and potential government incentives. We can undertake as little, or as much, of your project as you would like.

Requirement analysis

We analyze the compressed air equipment at your facility, its performance, condition, control mechanisms, and suitability. We ensure that storage, piping, and compressed air quality are in line with your requirements and best practices.

Turnkey design and installation

Everything we do is “in house.” Compressed air system design, air audits, leak detection, design, build, installation, and air compressor service are handled quickly and efficiently. This approach means that we manage every aspect of your project and create single source supply for you and your organization.

Maintenance and repair

Whether you require emergency breakdown response, predictive, or preventative maintenance our team has you covered. Air end and motor service and rebuilds, piping system, and analysation are also available.

Related products

Accessories

Whatever it is you're looking for, our accessories range from the gauges and valves in the compressor room, all the way through to the hoses, air knives, nozzles, and blow guns at the points of use.

Blowers

Kaeser blowers are built for a lifetime of high performance, low energy costs, and best in class performance, with flow rates between 170 ICFM and 2603 ICFM.

Compressors

Our range of air compressors includes reciprocating piston, oil free, and oil injected rotary screw air compressors, from 3hp up to 700hp, and everything in between. If you do not know what you are looking for, we can assist with that too.

Pipe Work

Our mechanical team is TSSA certified to perform all types of pipe work. Stainless steel, copper, aluminum, galvanized and black steel pipe are available for supply and installation. Our team also specializes in ductwork, machinery moving, and rigging applications.