Air Receiver Tanks

Investing in an air receiver tank is a wise best practice. The tank increases system storage, slows the velocity of compressed air traveling through the pipework and assists with moisture removal and pressure equalisation. When a compressor switches from load to idle, it reduces the amount of power being consumed by its electric motor. Therefore an air receiver tank is a one time purchase, requiring little, or no maintenance and producing an excellent ROI. This should always be the target, which is why we always say “you can never have enough storage.”

In addition, the tank acts as a buffer for the compressor’s control valving. This prevents rapid cycling and premature wear and tear of valves inside the machine, which, in turn, reduces maintenance costs.

The tank also slows the velocity of air and creates a cyclonic motion as the air passes through it. This reduces the oil/water condensate load on all downstream clean air treatment filters and dryers, further reducing filter and other maintenance costs.

Did you find what you were looking for?

The system

Air Receiver tanks are an important piece of any compressed air system. Creating storage provides multiple benefits, from moisture removal, pressure equalisation and energy conservation. In a perfect world, installing both wet, (upstream of clean air treatment), and dry, (downstream of clean air treatment) storage tanks is a best practice.

Frequently asked questions

What else do Kaeser and Air Solutions Canada offer?

We supply, design, build, and install Kaeser compressors, rotary vacuum, rotary blowers, and a full line of clean air treatments.

Do you offer delivery and pickup services?

Yes, we provide delivery and pickup for all our rental equipment and compressed air solutions, scheduled at your convenience, and typically in our own delivery truck.

How it works

Our tried-and-tested approach to get you a reliable compressed air solution at the lowest possible cost of ownership looks like this:

Discovery call

Our solutions specialist visits your facility to discuss your current situation, pain points, future plans, and potential government incentives. We can undertake as little, or as much, of your project as you would like.

Requirement analysis

We analyze the compressed air equipment at your facility, its performance, condition, control mechanisms, and suitability. We ensure that storage, piping, and compressed air quality are in line with your requirements and best practices.

Turnkey design and installation

Everything we do is “in house.” Compressed air system design, air audits, leak detection, design, build, installation, and air compressor service are handled quickly and efficiently. This approach means that we manage every aspect of your project and create single source supply for you and your organization.

Maintenance and repair

Whether you require emergency breakdown response, predictive, or preventative maintenance our team has you covered. Air end and motor service and rebuilds, piping system, and analysation are also available.

Related products

Tanks

Horizontal and Vertical air receiver storage tanks are available, with the most common sizes kept in stock at our Hamilton warehouse.

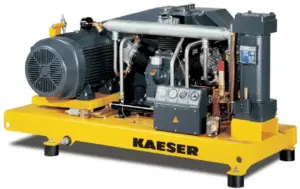

Boosters

When compressed air or gas applications require higher pressure than a “standard” air compressor can produce, high pressure booster compressors are an economical and effective solution.

Accessories

Whatever it is you're looking for, our accessories range from the gauges and valves in the compressor room, all the way through to the hoses, air knives, nozzles, and blow guns at the points of use.

Compressors

Our range of air compressors includes reciprocating piston, oil free, and oil injected rotary screw air compressors, from 3hp up to 700hp, and everything in between. If you do not know what you are looking for, we can assist with that too.

Condensate Management

Disposing of the compressed air oil/water condensate byproduct, created by your compressor station, carries big legal, and environmental responsibilities. The person knowingly discharging oil to drain, is responsible.

N2 and O2 Generators

Reliable Nitrogen Supply, Anytime, Anywhere – Peak i-Flow Nitrogen Generators: Uninterrupted 24/7 operation ensures a consistent, on-demand nitrogen gas flow for various applications, boasting flow rates of up to 11,845 SCFH and purity levels reaching up to 99.9995% (5 PPM).