Mansfield Ski Club

- Reduced maintenance costs

- Reduced noise and vibration pollution

- Eliminated the need for cooling water

- Increased snow production

Mansfield Ski Club

Mansfield Ski Club is a private ski club located north of Toronto, just south of Creemore, Ontario. Mansfield offers industry-leading programs for every age, ability, and motivation. Programs are delivered by experienced and highly certified coaches and instructors. The club includes 17 runs, 7 lifts, and 3 freestyle terrain parks, with 100-percent snowmaking coverage.

Aging, inefficient machines

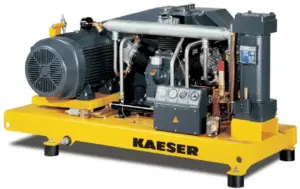

Mansfield Ski Club was using two 200-hp (149-kW), 1960s reciprocating piston air compressors (pictured right) to power their snowmaking equipment.

The aging and inefficient machines required constant maintenance and expensive annual rebuilds. The cost of servicing the equipment, sourcing obsolete parts, supplying cooling water, and powering the existing equipment had become exorbitant and unmanageable.

Excessive noise and vibration were also a problem.

Analysis. Recommendations. Installation.

- We began with our no-obligation discovery call.

- Then we conducted an Air Demand Analysis (ADA) study to establish system cfm demand, system pressure status, and power consumption.

- Our resulting engineer’s report revealed that replacing the two existing compressors with a brand new, state-of-the-art Kaeser station would result in significant benefits.

- We installed four new 100-hp, (75-kW), air-cooled, Kaeser rotary screw air compressors, complete with air dryers (top, left).

- The new compressed air system is beautifully orchestrated by Kaeser’s master controller, the Sigma Air Manager 4.0 (bottom, left). SAM ensures that the four compressors equally share the workload and perfectly match cfm demand, cascading “on” as demand increases, and “off” when cfm requirements drop. This mode of operation eliminates the need for expensive and often troublesome variable speed drives.

Where do we even begin?

-

The new compressed air system has vastly reduced maintenance costs and eliminated the need to source expensive and obsolete parts.

-

Excessive noise and vibration pollution are gone, eliminating stress on staff, visitors, and wildlife.

-

System pressure storage and pulsation are now stable.

-

Cooling water is no longer needed, further reducing costs and environmental impact.

-

Our solution includes inline, oil, and particulate removing filtration, guaranteeing ISO 8573 Compressed Air Class 1.4.1.

-

Heat recapture produces 635,000 btu/hr of space heating.

-

SAM has enabled a seamless interface with Mansfield’s building management system. With four compressors in place, service can now be completed at any time, as the station provides complete emergency and service backup redundancy.

Less money. More snow.

-

Together, these results have enabled the Mansfield Ski Club to reduce their carbon footprint and drive down the cost of ownership of their compressed air equipment.

-

Their annual hydro bills alone were reduced by $75,000. In addition to those savings, on the ski club’s behalf, Air Solutions Canada applied for and secured a Save-On-Energy incentive worth $31,320. This assistance substantially offset the cost of the retrofit.

-

With the new Kaeser system, Mansfield Ski Club was able to achieve an ROI in less than 12 months.

-

They will be able to produce more snow in the 2022 season compared to previous years.

“We have full confidence and peace of mind in the new Kaeser compressors as an integral part of our snowmaking system. Since the installation, we have received an abundance of rave reviews from our membership, guests and staff about the overall increase in snow quality.”

Scott Dermont

Operations Manager

Mansfield Ski Club

Related products

The ultimate guide on rightsizing your compressed air system

Choosing the right compressed air system is crucial to minimize the total cost of ownership. How do you calculate the air demand in flow rate (CFM) and pressure (PSIG), what's the power requirement (V), and how does that translate in a compressed air system with one or more compressors (hp)?

Download our Comprehensive Guide for Choosing the Right Compressor Size!