Our compressed air demand analysis identifies leaks, inefficiencies, and demand issues — so you can size your system right and cut energy and downtime costs.

Reliable, Expert Air Compressor Service in Southern Ontario

Air Solutions Canada specializes in comprehensive compressed air solutions designed to keep your operations running smoothly. Our expert team includes Millwrights, Electricians, Control Specialists, Refrigeration Dryer and Chiller Mechanics, Desiccant and Breathing Air Technicians, and Hospital Licensed Tradespeople—all factory-trained and certified. With 24/7 direct emergency support, you always speak directly to a technician, ensuring immediate, skilled assistance whenever you need it.

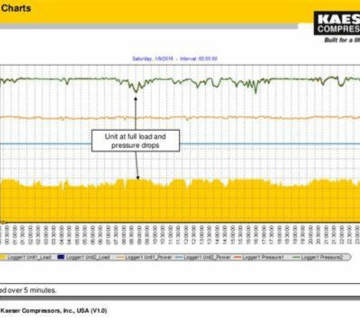

Air Demand Analysis, (ADA)

Compressed Air Service

Reliable 24/7 air compressor service and repair from experts you can trust. Air Solutions Canada keeps your compressed air systems running with preventive maintenance, efficient repairs, and custom solutions for every brand and need.

Dry Ice Cleaning

Safe, eco-friendly cleaning method removing contaminants from air and oil after-coolers, improving system efficiency without downtime or messy overspill from power washing.

Energy Efficiency

We identify and eliminate waste, leaks, and inefficiencies through air demand analysis, leak detection, and preventative maintenance—significantly lowering energy costs and improving performance.

KAirFree

Get guaranteed compressed air without owning the equipment—pay only for the air you use, while all compressor maintenance, repairs, and support are fully managed for you.

Leak Detection

Reduce energy costs significantly through professional compressed air audits and acoustic leak detection, quickly identifying leaks for immediate ROI and improved efficiency.

Lubricants/Oil

Optimize your compressor’s performance and lifespan with precisely selected lubricants ensuring effective lubrication, cooling, and sealing for reliable long-term operation.

Parts & Components

Immediate access to Ontario's largest compressed air parts inventory—over $1 million in critical spare parts and lubricants—ensuring minimal downtime.

Pipework Installations

Professional, TSSA-approved pipework installation services optimize airflow and efficiency, reducing leaks, enhancing reliability, and significantly lowering your compressed air costs.