Improve your system performance and reduce your total cost of ownership with a comprehensive compressed air system audit completed by a professional engineer.

Operational excellence is key to remaining competitive. Improving production rates, raising quality, and minimizing resource costs drive competitive success. Your compressed air system impacts all three and presents a great opportunity for improvement in your plant.

In the course of helping thousands of customers save millions of dollars through compressed air energy best practices we have improved conventional air audit techniques to develop our unique Kaeser Air Demand Analysis (ADA) program. No other approach to compressed air system analysis offers this combination of comprehensiveness, convenience, and affordability.

Compressed air is likely your biggest energy user.

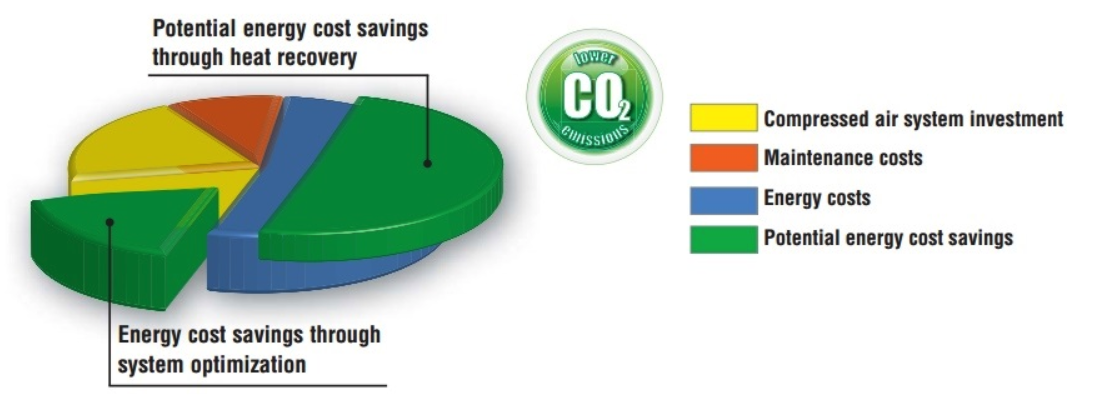

Most compressed air systems operate inefficiently. Improper adjustments, leaks, artificial demand, and poor system design all contribute to unnecessarily high energy cost and usage. Many of these same systems can't deliver the desired air volume at the needed pressure. This results in lower production rates and quality, as well as higher life cycle costs. Many facilities can achieve savings up to 50% by studying and optimizing their compressed air systems.

There are other important incentives to reduce energy consumption. From the consumers' perspective, the industrial "carbon footprint" is a growing concern, so environmental stewardship is also a strategic issue. According to the latest estimates, optimizing existing industrial motor-driven systems (including compressors) could reduce energy consumption by as much as 7 percent. If this is one of your strategic goals, examining your compressed air system will yield significant improvements.

Kaeser is a leader in making the most reliable and energy-efficient compressed air products you can buy. Still, having energy-efficient components is only part of the efficiency picture and that the greatest efficiency gains are often achieved through system design. For many years, Kaeser has been helping customers do just that: design better compressed air systems that are dependable and energy-efficient. They've led the way in promoting proper piping, storage, and controls, while others continue to focus merely on the initial capital cost of the equipment.

Benefits of Air Demand Analysis

- Significantly reduce energy costs by identifying and eliminating inefficiencies in your system.

- Reduce production scrap/waste by providing consistent pressure to production equipment.

- Cut air compressor maintenance costs by optimizing run time and reducing excess cycling.

- Reduce production equipment maintenance costs through improved air quality.

- Minimize downtime by reducing compressor maintenance intervals.

- Reduce your carbon footprint with lower energy consumption.

- Help qualify for utility rebate programs to pay for system upgrades.

The ADA process

Suitable for analyzing large or small systems, Kaeser's ADA is an exceptional tool. With the data we gather through our compressed air audit, our specialists identify areas for improvement in energy savings, air delivery, and pressure stability throughout your plant.

Our field service experts have the knowledge, experience, and tools to study true life cycle costs. They can evaluate your air system and make solid recommendations that will greatly reduce your energy costs and even increase productivity. More efficient systems idle less, run less, and as a result, last longer.

Site survey

The first step in an Air Demand Analysis is to become familiar with your air system. Discussing your goals for the assessment, areas of concern, production needs, and air quality issues help lay the groundwork for a successful optimization project. From there, we review all the component of your air system, including:

- Compressor controls

- Overall system controls

- Intermediate storage and distribution piping

- Air treatment equipment

We also investigate cycles and trends in plant processes to see how they relate to system dynamics and identify possible correlations with system performance issues. Using this information, we can baseline system performance more accurately and build a better system demand profile that takes into account dynamic production needs.

Your Air Solutions Canada field representative will visit your site to:

- Collect detailed information on your system components, environmental conditions, and physical layout.

- Collect appropriate supporting graphical data such as plant blueprints, schematic drawings, sketches, and photographs.

- Gather input on specific problems your plant is currently facing and discuss desired outcomes.

Data logging

To obtain a detailed, accurate picture of your compressed air demand and system dynamics, we install a variety of instruments and sensors customized to your unique system. Since you pay for kWh, we measure kilowatts—not amps—to give the most cost-effective calculation. This approach creates a complete picture of system activity - including leaks, which are often most apparent during off-peak production periods.

Comprehensive analysis

Using proprietary KAESER ADA software, we identify waste and poor practices, such as leaks or artificial demand caused by operating at unnecessarily high pressures. It also shows energy loss due to pressure drops in distribution piping.

We create detailed time-stamped charts from the recorded data. These are used to analyze your system from several perspectives and offer insight into your operating activities and corresponding air requirements.

This step also helps to identify deficiencies in the air supply, storage, or piping along with any control issues.

Kaeser Energy Savings System (KESS)

We use powerful Kaeser Energy Savings System (KESS) software to simulate power requirements of different system scenarios. This helps identify solutions that will achieve the greatest efficiency without compromising pressure/flow requirements or system reliability.

Analysis & recommendations

Your Air Demand Analysis isn't complete until we issue a final analysis and recommendations. This includes a side-by-side comparison of multiple scenarios showing their purchase price, operational cost, and savings in different load conditions.

Recommendations often focus on making adjustments to controls, storage, or piping rather than buying new equipment. Armed with these ideas, you'll be able to determine the most cost-effective system changes with reduced energy consumption.

Measurable result

Here are some examples of recent Kaeser ADAs that delivered significant and immediate benefits to customers:

- A precision metal fabricator was using two 40-hp modulating compressors to supply their flow, but struggling with pressure fluctuations. An ADA revealed the system was oversized and a single 20 hp dual control compressor could handle the demand. This has reduced their energy costs by 40%—even though their average demand has increased by 28%.

- A music studio equipment manufacturer struggled with pressure, flow, and air quality problems. The ADA recommended a system that would deliver steady pressure and flow and an energy-efficient dryer to address the moisture problems for $36,110 in annual energy savings.

- A plant manufacturing turbines for hydroelectric power plants reduced their system-specific power from 62.0 kW/100 cfm down to 16.7 kW/100 cfm by switching from multiple modulating control compressors to energy-efficient rotary screw compressors with a system master controller.

- A furniture manufacturer struggled with vacuum hold-down. The ADA identified flow—not vacuum—was the problem and designed a new system with vacuum blowers. This solution reduced the horsepower by 200 hp and is saving them $99,000 in energy and maintenance costs every year.

- At a metal products plant, an ADA identified $51,000 in savings for fixing system leaks in $17,000 in savings for adding proper system controls.

- Thanks to recommendations from an ADA, a Tier I automotive parts supplier was able to reduce their power consumption by 865,440 kWh—the equivalent of removing 100 homes from the power grid for a year. The energy and maintenance savings totalled $133,720. On top of that, they received a utility rebate of $71,579.

- An automotive parts manufacturer with multiple, uncontrolled centrifugals was spending $699,799 in energy costs and approximately $109,000 on annual maintenance. The ADA identified $129,046 in energy savings—along with drastically reduced maintenance costs—for a 17-month simple payback period.

- A cement manufacturer conducted ADA's at five of their plants. Implementing the recommendations resulted in a 12,658-ton reduction in CO² and average monthly savings amongst the plants as high as 64%.

Whether your motivations are financial or environmental, an efficient air system will deliver the right amount of air at the lowest life cycle cost.

Optimise your compressed air station with the ADA & KESS from KAESER

Are you looking to optimise or expand your existing compressed air station? Are you aware of the possible weak points within your compressed air station? Or, are you planning to install a new compressed air station which precisely meets your needs?

With Kaeser’s Air Demand Analysis (ADA) and the Kaeser Energy Saving System (KESS), our compressed air experts can provide you with the full picture when it comes to your compressed air station – and create the optimum solution for outstanding compressed air supply efficiency and dependability.

Related products

Controllers

Kaeser's Sigma air Manager, SAM 4.0 provides complete system management for air compressors, blowers and vacuums, from a large easy to read screen, with remote access options.

Compressors

Our range of air compressors includes reciprocating piston, oil free, and oil injected rotary screw air compressors, from 3hp up to 700hp, and everything in between. If you do not know what you are looking for, we can assist with that too.

Tanks

Horizontal and Vertical air receiver storage tanks are available, with the most common sizes kept in stock at our Hamilton warehouse.

Pipe Work

Our mechanical team is TSSA certified to perform all types of pipe work. Stainless steel, copper, aluminum, galvanized and black steel pipe are available for supply and installation. Our team also specializes in ductwork, machinery moving, and rigging applications.

The ultimate guide on rightsizing your compressed air system

Choosing the right compressed air system is crucial to minimize the total cost of ownership. How do you calculate the air demand in flow rate (CFM) and pressure (PSIG), what's the power requirement (V), and how does that translate in a compressed air system with one or more compressors (hp)?

Download our Comprehensive Guide for Choosing the Right Compressor Size!

Why work with Air Solutions Canada

Working with the largest compressed air team in Southern Ontario has many benefits

Fastest emergency service

We guarantee a same day visit with dedicated emergency service technicians, on call 24/7. Every vehicle is equipped with a breakdown “crash kit” so in most cases we solve your problem immediately. Our 1st time fix rate is currently 93%.

Largest equipment inventory

We can quickly address all your compressed air needs and solve any emergency with over $2M of inventory, including an extensive “ready to go”, fleet of electric and diesel-driven compressors, spare parts and filters for most compressor brands.

Technicians dedicated to you

You have a dedicated primary and secondary technician at your disposal. They have all your equipment information and service history at their fingertips to ensure fast, familiar service and personalized support for every visit.

Competitive Pricing

We get preferential pricing and pass discounts on to our customers. We make reliable compressed air service affordable and easy to budget with flexible payment terms and various lease, rent and PAYG options.

Frequently asked questions

See All Frequently Asked QuestionsWhat else do Kaeser and Air Solutions Canada offer?

We supply, design, build, and install Kaeser compressors, rotary vacuum, rotary blowers, and a full line of clean air treatments.

Do you offer delivery and pickup services?

Yes, we provide delivery and pickup for all our rental equipment and compressed air solutions, scheduled at your convenience, and typically in our own delivery truck.