Compressed air systems are essential for running machinery and other production operations, in a multitude of industries. Ironically, the cost and electrical power required to own and operate a compressed air system can be highly expensive, and most users consciously recognize this. However, despite this knowledge, they allow air leaks to quietly eat away at the companies’ bottom line profits, while trying to cut expenditure in other critical areas of their maintenance operation to balance budgets.

Does this sound familiar?

Industrial manufacturers and other production or service establishments disregarded compressed air leaks in their processes for many years. However, the industry standard has changed drastically, and now, not only does conserving this resource help save money, but it can also boost machinery performance while enhancing product quality. Compressed air is one of the most expensive energy sources in an industrial facility, and according to the Department of Energy (DOE), on average, compressed air systems that are not regularly maintained after installation could be losing 20 to 30% of compressed air in leaks.

In short, air leaks might be costing your business considerable amounts of money through unnecessary electrical costs, created by “easy to combat” compressed air leaks.

If you choose to ignore the negative effects that air leaks may have on your yearly energy costs, it’s important to note that leaks will still reduce operating efficiency, and lead to lost productivity because of the system's unavoidable decline in air pressure. This might lead to shorter equipment service lifespans and less effective use of processes, air tools, spray paint finishes, cylinders, valves, and “blow offs” which use compressed air.

Unfortunately, leak identification and repair are never one-time events. The compressed air system will likely require more maintenance as it matures, or changes over time. Leak detection and repairs must be viewed as a continuous program if you want long-term outcomes. The simplest method to make sure leak detection is remembered is to create a program for continuous improvement. You might want to talk to your compressed air service provider about incorporating leak detection into your preventative maintenance schedule as part of this plan. Energy savings from a continuous leak detection audit and repair program will quickly provide a rapid ROI. In addition, you will benefit from improved manufacturing equipment performance and less downtime.

Related products

Compressors

Our range of air compressors includes reciprocating piston, oil free, and oil injected rotary screw air compressors, from 3hp up to 700hp, and everything in between. If you do not know what you are looking for, we can assist with that too.

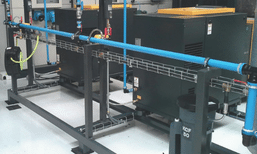

Pipe Work

Our mechanical team is TSSA certified to perform all types of pipe work. Stainless steel, copper, aluminum, galvanized and black steel pipe are available for supply and installation. Our team also specializes in ductwork, machinery moving, and rigging applications.

The ultimate guide on rightsizing your compressed air system

Choosing the right compressed air system is crucial to minimize the total cost of ownership. How do you calculate the air demand in flow rate (CFM) and pressure (PSIG), what's the power requirement (V), and how does that translate in a compressed air system with one or more compressors (hp)?

Download our Comprehensive Guide for Choosing the Right Compressor Size!

Why work with Air Solutions Canada

Working with the largest compressed air team in Southern Ontario has many benefits

Fastest emergency service

We guarantee a same day visit with dedicated emergency service technicians, on call 24/7. Every vehicle is equipped with a breakdown “crash kit” so in most cases we solve your problem immediately. Our 1st time fix rate is currently 93%.

Largest equipment inventory

We can quickly address all your compressed air needs and solve any emergency with over $2M of inventory, including an extensive “ready to go”, fleet of electric and diesel-driven compressors, spare parts and filters for most compressor brands.

Technicians dedicated to you

You have a dedicated primary and secondary technician at your disposal. They have all your equipment information and service history at their fingertips to ensure fast, familiar service and personalized support for every visit.

Competitive Pricing

We get preferential pricing and pass discounts on to our customers. We make reliable compressed air service affordable and easy to budget with flexible payment terms and various lease, rent and PAYG options.

Frequently asked questions

See All Frequently Asked QuestionsWhy would I need to rent compressed air equipment?

There are many reasons why you might need to rent compressed air equipment. For example, you might have a temporary need for additional air capacity for a project, or your existing equipment might be temporarily out of service.

What types of compressed air equipment do you rent?

We rent a variety of compressed air equipment, including air compressors, air dryers, air receivers, and accessories such as hoses, fittings, and filters. We have all kinds of coverage for most applications, including oil injected, oil free, and breathing air.

How do I know what type of compressed air equipment I need?

Our team of experts can help you determine the right equipment for your specific needs. We'll ask you about your air requirements, the size of your operation, flow, pressure, piping, hoses, power, or fuel, and any specific challenges or constraints you might be facing.

How long can I rent compressed air equipment for?

We offer rental periods of varying lengths, from a few days to several months. Longer rental durations can be converted into rent to own options too, where we credit you for the majority of the rental costs and sell the equipment to you when funds become available. We can work with you to determine the rental period that best meets your needs.

What if I need compressed air equipment for an emergency situation?

We understand that emergencies can happen at any time, and we're here to help. We offer 24/7 emergency service, and can provide equipment quickly to help you get back up and running as soon as possible. Our technicians can assist with set up, start up and commissioning, if required.