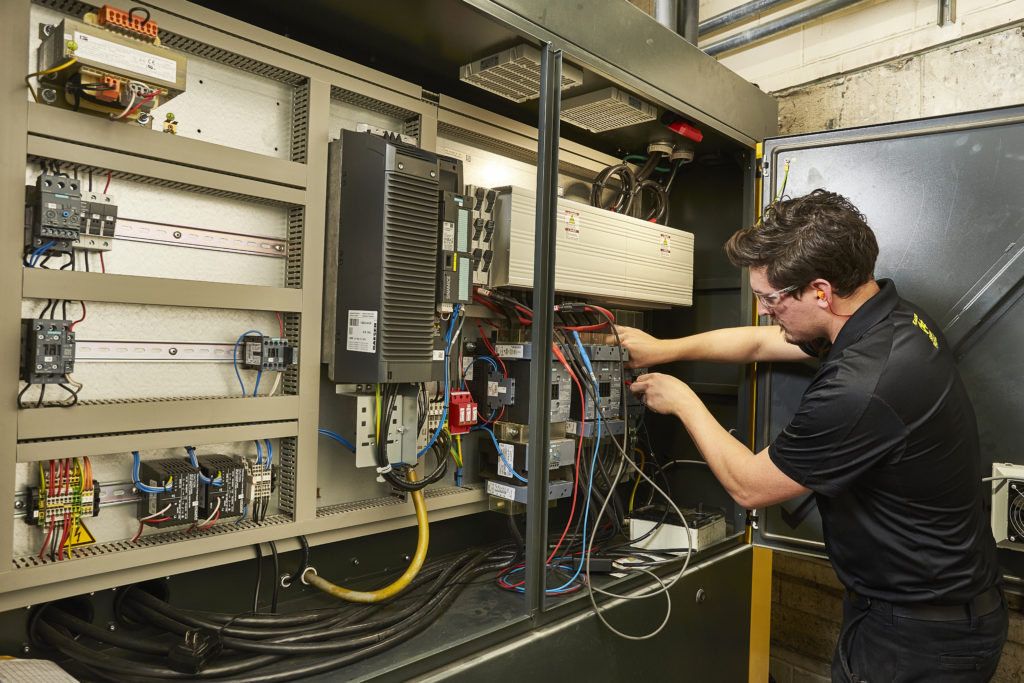

At Air Solutions Canada, our air compressor preventative maintenance services keep your compressed air system operating at peak performance. Delaying air compressor maintenance leaves your operations vulnerable to unplanned downtime, costly repairs, and unnecessary stress and expense. By making proper maintenance a top priority, you ensure reliable operation, extend equipment life, and avoid the inconvenience of emergency fixes. Backed by Ontario's largest factory-trained, air compressor service team, we help plants design a maintenance schedule that keeps every air compressor running strong.

Why Preventative Maintenance for Air Compressors Matters

Preventative and predictive air compressor maintenance represent the foundation of any dependable compressed air system. When air compressor maintenance is treated as an essential part of plant operations, and not just an afterthought, then it reduces equipment failure, improves safety, and maximizes efficiency.

Every component of your compressed air equipment, from the air intake filter to the discharge valves, relies on regular inspection, cleaning, and timely part replacement to function optimally. Overlooking these steps risks increased pressure drops, oil, dirt and water intrusion, air leaks, premature component failure, and reduced compressor performance. It’s not just about avoiding expensive repairs; it’s about delivering the consistent system performance, safety, and reliability that your business needs.

What’s Included in an Air Compressor Maintenance Plan?

Our air compressor maintenance plans are tailored to your equipment, its run hours, and the environment they operate in. Every plan includes:

- Air filter and oil filter element replacement to ensure the efficient capture of unwanted contaminants from reaching your compressor.

- Lubricant and oil level checks, plus scheduled coolant replacement to reduce wear and avoid equipment damage.

- Valve and moving part inspections, ensuring your compressors maintain optimal performance for every shift.

- Inspection and maintenance of dryers, coolers, and all compressed air equipment—catching inefficiency or early signs of failure.

- Immediate and 24/7 access to $1 million in genuine compressor parts, for most major brands of compressors, specialized diagnostic tools, and fully equipped field vehicles for efficient repairs.

- In-house, certified technicians perform all work—never outsourcing compressor maintenance.

Whether you run rotary screw, piston, vane, or oil-free air compressors, we support every brand and model with our experienced team.

Key Benefits of Routine Air Compressor Maintenance

Routine maintenance is more than a safeguard—it's an essential part of a reliable operation. The advantages of a smart, proactive plan include:

- Increased equipment lifespan through regular inspections and parts replacement, including critical air, oil, and separator filters.

- Reduced risk of unexpected compressor breakdowns and costly repairs.

- Consistent, high system performance and steady air pressure.

- Lower total cost of ownership for your entire compressor fleet.

- Enhanced safety for staff with fewer emergency incidents and reduced risk of compressor failure.

- Improved efficiency, decreased energy consumption, and fewer production interruptions.

- Reduced buildup and carryover of dirt, oil and water, minimizing piping, valve, cylinder and air tool wear and corrosion.

- Compliance with industry standards and all regulatory requirements, including TSSA pressure relief valve testing, and local ministry oil/water condensate discharge rules.

- Greater peace of mind thanks to a detailed maintenance schedule and our expert air compressor service team. All service visits are pre-scheduled around your production and equipment availability.

The Consequences of Skipping Maintenance

When compressor maintenance is neglected or delayed, the risks multiply quickly:

- Unplanned downtime and costly interruptions in production.

- Equipment failure, including catastrophic compressor damage requiring overhaul or replacement.

- Pressure drops, air leaks, and corrosion disrupt performance.

- Safety incidents that could have been prevented with proper maintenance.

- Emergency repairs, stress, and unplanned expenses erode profits and morale.

A robust preventative maintenance plan is always more affordable and effective than dealing with the fallout from a major breakdown. It’s a case of “pay me now, or pay me much more later.”

Enhanced Functionality: Smart Technology & Expert Support

Air Solutions Canada complements expert technician care with leading-edge digital solutions. As a Kaeser dealer, we offer the Sigma Air Manager 4.0 (SAM), a state-of-the-art remote monitoring and diagnostics platform. SAM tracks system performance in real time, detects air leaks and pressure drops, and provides alerts for routine inspection and predictive maintenance. By integrating SAM with your compressed air equipment, you gain a deeper level of oversight and the ability to schedule service at the optimal time. Our combination of advanced diagnostics, substantial parts inventory, and a skilled in-house team ensures that your plant achieves maximum uptime, system efficiency, and peace of mind.

Air Solutions Canada provides comprehensive coverage 24-7, all year round.

Related products

Blowers

Kaeser blowers are built for a lifetime of high performance, low energy costs, and best in class performance, with flow rates between 170 ICFM and 2603 ICFM.

Vacuums

Kaeser's Rotary screw vacuum packages are the perfect solution to industrial Vacuum applications. Featuring our award-winning Sigma Profile™ airend. Our range of machines produce 166 to 551 acfm.

Boosters

When compressed air or gas applications require higher pressure than a “standard” air compressor can produce, high pressure booster compressors are an economical and effective solution.

Accessories

Whatever it is you're looking for, our accessories range from the gauges and valves in the compressor room, all the way through to the hoses, air knives, nozzles, and blow guns at the points of use.

Dryers

Selecting the right dryer and filtration to ensure your facility receives clean, dry compressed air consistently, depends on many things. Our clean air selection process is based around ISO 8573.1 quality class standards.

Compressors

Our range of air compressors includes reciprocating piston, oil free, and oil injected rotary screw air compressors, from 3hp up to 700hp, and everything in between. If you do not know what you are looking for, we can assist with that too.

Filters

If you are looking for assistance in the filtration of dirt, oil, water, bacteria, hydrocarbons, oil odor or vapor, we have a filter, or an element to capture unwanted contaminants you need to stop. Compressed air, inert gases, liquids, ambient air, and water filtration is what we do best.

Tanks

Horizontal and Vertical air receiver storage tanks are available, with the most common sizes kept in stock at our Hamilton warehouse.

Condensate Management

Disposing of the compressed air oil/water condensate byproduct, created by your compressor station, carries big legal, and environmental responsibilities. The person knowingly discharging oil to drain, is responsible.

N2 and O2 Generators

Reliable Nitrogen Supply, Anytime, Anywhere – Peak i-Flow Nitrogen Generators: Uninterrupted 24/7 operation ensures a consistent, on-demand nitrogen gas flow for various applications, boasting flow rates of up to 11,845 SCFH and purity levels reaching up to 99.9995% (5 PPM).

Pipe Work

Our mechanical team is TSSA certified to perform all types of pipe work. Stainless steel, copper, aluminum, galvanized and black steel pipe are available for supply and installation. Our team also specializes in ductwork, machinery moving, and rigging applications.

The ultimate guide on rightsizing your compressed air system

Choosing the right compressed air system is crucial to minimize the total cost of ownership. How do you calculate the air demand in flow rate (CFM) and pressure (PSIG), what's the power requirement (V), and how does that translate in a compressed air system with one or more compressors (hp)?

Download our Comprehensive Guide for Choosing the Right Compressor Size!

Why work with Air Solutions Canada

Working with the largest compressed air team in Southern Ontario has many benefits

Fastest emergency service

We guarantee a same day visit with dedicated emergency service technicians, on call 24/7. Every vehicle is equipped with a breakdown “crash kit” so in most cases we solve your problem immediately. Our 1st time fix rate is currently 93%.

Largest equipment inventory

We can quickly address all your compressed air needs and solve any emergency with over $2M of inventory, including an extensive “ready to go”, fleet of electric and diesel-driven compressors, spare parts and filters for most compressor brands.

Technicians dedicated to you

You have a dedicated primary and secondary technician at your disposal. They have all your equipment information and service history at their fingertips to ensure fast, familiar service and personalized support for every visit.

Competitive Pricing

We get preferential pricing and pass discounts on to our customers. We make reliable compressed air service affordable and easy to budget with flexible payment terms and various lease, rent and PAYG options.

Frequently asked questions

See All Frequently Asked QuestionsHow can a preventative maintenance plan save my company money?

Air compressor preventative maintenance plans are a small investment compared to the costs of equipment failure and unplanned downtime. When preventative maintenance is scheduled and performed by qualified technicians using the right lubricants, air filters, in-line filter elements, and spare parts, the risks of breakdown, efficiency loss, or safety hazards are minimized.

Without a plan, costs can quickly add up:

- Lost production due to equipment or system failure

- Compressor rental and hook-up fees

- Rush shipping for parts and emergency labor

- Emergency repair costs and overtime

- Hasty decisions under stress

- Irreparable damage, or catastrophic compressor failure

- Unplanned replacement costs, pressure drops, and system inefficiencies

- Panic, accidents, and potential safety or environmental risks

How much does a preventative maintenance plan cost, and how much do I stand to save?

The cost of a professional maintenance plan depends on the type and size of your compressed air equipment, its condition, system complexity, pressure requirements, and operational hours. The accessibility and availability will also impact the cost of labour, with “normal” working hours being the least expensive choice.

Savings come from:

- Strategic purchasing of parts and lubricants

- Oil analysis sampling and vibration testing provide trends to indicate component and material decay

- Avoiding major equipment repairs, emergency parts delivery, overtime costs, and lost production

- Maintaining peak efficiency, system pressure, and safe operation

- Reducing risk of accidents, corrosion, wear and tear component failure, and catastrophic compressor damage. A single instance of unexpected downtime can result in expensive repairs, unbudgeted costs, or even full equipment replacement, making a proactive maintenance plan a smart investment.

What payment options do I have for a maintenance plan?

We offer flexible payment options:

- Pay-as-you-go: Fixed rates for time and materials, billed as services, labour and parts are consumed.

- Fixed fee: Set annual cost based on your machine usage, covering all routine maintenance, inspections, lubrication, filter replacement, and more.

- Payment plans: Spread costs evenly over semiannual, quarterly, or monthly payments; over 75% of clients choose this predictable approach. Fixed budget billing helps to stabilize expenditure.

Can I purchase a preventative maintenance plan from Air Solutions Canada for non-Kaeser equipment?

Absolutely. Our technicians service all brands, models, and types of air compressors, dryers, filters, and compressed air equipment—anywhere, anytime, as needed.

If production times are reduced during the year, how does that impact our maintenance plan?

Our flexible plans adapt to your plant’s operating changes. If your usage drops and the fixed payment plan results in a credit, we issue a refund or adjust your service as needed. Your air compressor maintenance is always matched to your real requirements.

Is there technology that helps predict maintenance issues?

Yes. As a Kaeser dealer, we offer Sigma Air Manager 4.0 (SAM), which can remotely monitor compressor system performance, analyze for air leaks or pressure drops, and provide alerts for routine or predictive maintenance. This technology supports enhanced functionality—protecting your plant from unforeseen failure, maximizing efficiency, and enabling real-time system data analysis.

Are there specific types of businesses for which preventative maintenance plans work best?

Every business using compressed air equipment benefits from scheduled air compressor maintenance and professional inspections. Our plans are trusted by industries from food, beverage, brewing, dairy, and pharma, to automotive, textiles, electronics, and steel. Whether you run a single air compressor or a large-scale system with multiple machines, preventative maintenance increases machine life, safety, and reduces the risk of downtime or damage.

Do you outsource any of your maintenance work?

No, nothing is outsourced with Air Solutions Canada. We have one of the largest teams of compressed air service technicians in southern Ontario, including certified refrigeration technicians and millwrights. We have the in-house capability to directly handle any maintenance or service issues that arise.