How much could you save?

For most commercial compressed air systems, energy costs represent approximately 70% of the total lifetime expenditure. In fact, the amount of energy required to run a compressor for just one year will often exceed the compressor purchase price. Over the course of 10 years, energy costs typically total 70%, maintenance is 15%, and capital expenditure costs are 15% of the overall lifetime expenses.

"The bitterness of poor quality remains long after the sweetness of low price is forgotten" - Benjamin Franklin

Explore our energy and cost-reduction techniques!

The following examples demonstrate some of the techniques we can use to help you reduce your energy consumption and costs:

Air Demand Analysis (ADA)

Are you wasting compressed air?

When was the last time you performed an analysis of your system?

Our Air Demand Analysis (ADA) study measures your plant's compressed air consumption (cfm), system pressure (psig), and kW power consumption for each air compressor. These three profiles give us the information we need to pinpoint your exact energy losses and make recommendations to optimize your system.

Analysis takes place over a 9-day period and provides insight into 6 key areas:

- CFM consumption

- Peak demands

- Potential energy and cost savings

- Leaks

- Pressure swings and profiles

- Superficial uses

Your ADA Report will provide a detailed profile and current benchmark of your compressed air system with graphs and recommendations. Typical results pinpoint opportunities for significant savings through re-configuring and replacing equipment. We'll provide a separate quotation for supplying and installing what's required.

Contact us today to arrange your own Air Demand Analysis.

Leak detection

How much compressed air are you producing to feed compressed air leaks? We think you might be surprised at the answer and associated cost.

Generating compressed air is typically the fourth most expensive utility in an industrial facility. Compressed air leaks, from our experience, can equate to as much as 15% of compressed air demand. Most of these can be avoided and many of them are superficial.

Performing a leak detection, on a regular basis, is highly recommended "best practice".

Our technicians survey your facility with " state of the art" ultrasonic leak detection equipment to identify, locate and tag all compressed air related leaks. Our study begins at the generating plant and ends at point of use. Our report includes the cost to generate compressed air and the cost to repair your system.

Performance guarantee:

Our performance guarantee means that the savings we identify will exceed the cost of our study. If this is not the case, the study will be free of charge.

Contact us today to learn more.

Eyedro meters

Not happy with your electricity bills?

The best way to gain a clear picture of when and where electricity is being used in your plant is by measuring and monitoring your consumption in real time. This is an essential step in identifying energy saving opportunities. After all, you cannot improve what you do not measure.

Our award wining Eyedro Meters capture the kW consumption of every electrical motor in your facility. Up to 30 motors can be data logged via a single Eyedro meter, and the data gathered can be wirelessly and securely transmitted directly to your smartphone or computer.

Click here to see the live energy consumption at our own facility in Waterdown, Ontario.

Contact us today to try Eyedro Meters for yourself.

Heat recovery

Did you know that almost 99% of the energy inputted to a compressor is converted into heat? Through a variety of methods, that heat energy can be captured and reused within your facility for space, water, gas, and oil heating.

We'll help you identify your best opportunities for heat recovery and install and maintain the equipment you require.

Download this Heat Recovery document to learn more.

Flow meters

Would you like to measure and monitor compressed air flow in your system?

Air Solutions Canada can help by installing a clamp-on ultrasonic flow meter, which can be rented on a weekly or monthly basis. No disruption is required to your compressed air system or production at your facility.

Contact us today to learn more.

Kaeser variable frequency drive compressors

Using a Kaeser VFD, this Hamilton based company was able to reduce their annual energy consumption by 132,709 kWh. These reductions significantly reduced their energy costs and their carbon/emissions footprint.

Kaeser's VFD screw air compressors deliver up to 20% more air per kilowatt than typical industrial air compressors. That results an opportunity for substantial energy savings — we've helped hundreds of companies eliminate hundreds of thousands of kilowatt hours, which has a direct impact on their bottom line.

Explore our Kaeser product line here.

Click here for Compressed Air and Gas Institute (CAGI) data sheets on the efficiency of Kaeser’s compressed air equipment.

Kaeser Sigma Air Manager (SAM)

Sigma Air Manager controls all compressors, activating them only when needed. This improves pressure stability and system reliability. It also allows lower operating pressures, significantly reducing leaks and artificial demand. With the optional Sigma Air Control Plus software package, SAM can also provide continuous energy audit information. This data can be exported to Excel, to provide an energy saving report any time.

Maintenance costs can also be tracked by SAM and compressed cascading and demand rotation are perfectly orchestrated. This ensures equal running and selection of the best compressor to suit the plant demand.

SAM 4.0 communicates with the cloud and also has the ability to interface with your building management system (BMS), your smartphone, laptop, or tablet.

Contact us today to learn more.

Kaeser air main charging valve

Do you shut your compressors off on the weekend?

If you answered “yes” to this question, beware that unwanted oil, dirt and water contamination may be swept downstream into your production areas.

You can reduce exposure to this problem with Kaeser’s Air Main Charging Valve (AMCV), which releases compressed air into the main distribution pipework system by automatically opening and closing the valve in a controlled fashion. This prevents overloading the filters and dryers, eliminates damage to purification equipment, pipework and downstream equipment. The AMCV also increases the effectiveness of your air treatment equipment. It also pressurizes the entire air system in the shortest possible time to optimize energy efficiency.

Contact us today for more information.

Related products

Blowers

Kaeser blowers are built for a lifetime of high performance, low energy costs, and best in class performance, with flow rates between 170 ICFM and 2603 ICFM

Vacuums

Kaeser's Rotary screw vacuum packages are the perfect solution to industrial Vacuum applications. Featuring our award-winning Sigma Profile™, airend, our range of machines produce 166 to 551 acfm.

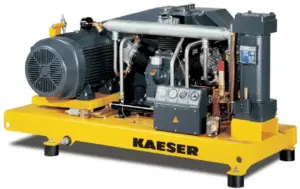

Boosters

When compressed air or gas applications require higher pressure than a “standard” air compressor can produce, high pressure booster compressors are an economical and effective solution.

Controllers

Kaeser's Sigma air Manager, SAM 4.0 provides complete system management for air compressors, blowers and vacuums, from a large easy to read screen.

Accessories

Whatever it is you're looking for, our accessories range from the gauges and valves in the compressor room, all the way through to the hoses and blow guns at the points of use.

Compressors

Our range of air compressors includes reciprocating piston, oil free, and oil injected rotary screw air compressors, from 3hp up to 660hp, and everything in between. If you do not know what you are looking for, we can assist with that too.

Dryers

Selecting the right dryer and filtration to ensure your facility receives clean, dry compressed air consistently, depends on many things. Our clean air selection process is based around ISO 8573.1 quality class standards.

Filters

If you are looking for assistance in the filtration of dirt, oil, water, bacteria, hydrocarbons, oil odor or vapor, we have a filter, or an element to capture whatever you need to stop. Compressed air, gases, liquids, ambient air, and water filtration is what we do best.

Tanks

Horizontal and Vertical air receiver storage tanks are available, with the most common sizes kept in stock at our Hamilton warehouse.

N2 and O2 Generators

Reliable Nitrogen Supply, Anytime, Anywhere – Peak i-Flow Nitrogen Generators: Uninterrupted 24/7 operation ensures a consistent, on-demand nitrogen gas flow for various applications, boasting flow rates of up to 11,845 SCFH and purity levels reaching up to 99.9995% (5 PPM).

Pipe Work

Our mechanical team is TSSA certified to perform all types of pipe work, ductwork, plumbing, machinery moving, and rigging.

The ultimate guide on rightsizing your compressed air system

Choosing the right compressed air system is crucial to minimize the total cost of ownership. How do you calculate the air demand in flow rate (CFM) and pressure (PSIG), what's the power requirement (V), and how does that translate in a compressed air system with one or more compressors (hp)?

Download our Comprehensive Guide for Choosing the Right Compressor Size!

Why work with Air Solutions Canada

Working with the largest compressed air team in Southern Ontario has many benefits

Fastest emergency service

With dedicated emergency service breakdown technicians, on call 24/7 we guarantee a same day visit.Every vehicle is equipped with a breakdown “crash kit” to provide us with the best potential opportunity to repair your issue during the first call.

Largest equipment inventory

With $2m of inventory in local warehouses, essential parts, and equipment are readily available. And with more than 50 compressors and dryers in our warehouse we can solve any emergency.

Technicians dedicated to you

We have primary and secondary technicians allocated for each customer, and they have all your information and equipment history on their iPad. It means that we know your particular service history and understand your equipment list.

Competitive Pricing

We get preferential pricing based on our volume purchases, and pass additional discounts on to our customers. We offer payment terms, lease and rent to own options & sell compressed air over the fence, by CFM consumption.

Frequently asked questions

See All Frequently Asked QuestionsWhat else do Kaeser and Air Solutions Canada offer?

Rotary Vacuum and Rotary Blowers are other facets of Kaeser's product range.

Air Solutions will design, build and install any of the Kaeser range of products, including compressors, vacuums, blowers and a full range of clean air treatments. Our turnkey approach to rigging, piping, ductwork and electrical, means that one call does it all.

Do you offer delivery and pickup services?

Yes, we offer delivery and pickup services for all of our rental equipment. We'll work with you to schedule a convenient time for delivery and pickup that works with your schedule.

Communities we serve

Blog

Our blogs are purposely written in laymen terms. Often our clients become experts in compressed air knowledge when they become heavily involved in a pneumatic project. Our blogs are designed to assist the most experienced engineer, and also the total rookie in better understanding compressed air best practices vicariously through our first hand experiences and case studies.