In the woodworking industry, compressed air is essential to power the machinery and tools that allow the production systems to run consistently and effectively. Pneumatic (air-powered) tools have become integral to woodworking. Their efficiency, durability, safety, and ease of use make them ideal choices for many applications. In larger manufacturing facilities, compressed air may also be used to power the solenoids inside the dust collector, the conveyor belts, power lifts, material handling equipment, hold-down rolls, and large industrial planers, lathes, turners, and other woodworking equipment. In nearly every step of the woodworking process, you'll find air compressors hard at work.

Compressed air purity

In factories and shops applying coatings, paint and varnishe, compressed air quality is to atomize and transfer paint onto doors, draws, panels and components. Because oil and water can cause damage to equipment, and the final product, it’s important that the compressed air you’re using is of high quality and high purity. To prevent unwanted contamination that create finishing issues such as Fish Eyes and Orange Peel, the compressed air filters, dryers, drain traps and cooling are important to select, size, install and maintain correctly. Our extensive range of clean air treatment products, and services can help you to mitigate against all of the unwanted pain points, and ensure up time, clean and dry compressed air in keeping with all of the health and safety requirements in Ontario.

Many facilities we visit have paint and coating sprayers breathing the compressed air. CSA Z180, is a standard to which this compressed air supply must conform to. Breathable compressed air quality testing must be performed every six months to ensure that the operators are ingesting safe compressed air, free of CO, taste, smell and other undesirable compressed air contaminants.

With this in mind, clean air treatment is of course an essential part of your system, comprising of filters, dryers, and catalytic converters, to provide you with the necessary levels of ISO 8573.1 compressed air quality class. Air Solutions Canada Inc. preventative maintenance plans and our knowledge of industry best practices, means that we maintain your equipment, and ensure it’s working efficiently. Some might say that it is impossible to associate the price of compressed air downtime with the cost of maintaining the equipment correctly. Our service division provides peace of mind for any facet of your compressed air generating station and its distribution network and accessories.

Air compressor systems in the woodworking industry

Selecting the appropriate compressed air system is critical for your operations, impacting not only operational efficiency, but also the safety of your staff, and quality of your products. Air Solutions Canada Inc. is here to assist you in navigating this selection process, offering an extensive portfolio of products and services specifically designed for the woodworking industry. From energy-efficient compressed air to sophisticated clean air treatment, we provide the necessary tools to design, build and maintain a reliable and safe compressed air supply. We help you optimize your operations, minimize, or reduce your environmental footprint, while increasing and sustaining up time and efficiency.

With Air Solutions Canada Inc. you can count on superior experience, case studies and testimonials at:

Related products

Blowers

Kaeser blowers are built for a lifetime of high performance, low energy costs, and best in class performance, with flow rates between 170 ICFM and 2603 ICFM

Vacuums

Kaeser's Rotary screw vacuum packages are the perfect solution to industrial Vacuum applications. Featuring our award-winning Sigma Profile™, airend, our range of machines produce 166 to 551 acfm.

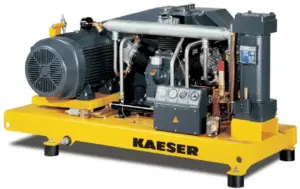

Boosters

When compressed air or gas applications require higher pressure than a “standard” air compressor can produce, high pressure booster compressors are an economical and effective solution.

Controllers

Kaeser's Sigma air Manager, SAM 4.0 provides complete system management for air compressors, blowers and vacuums, from a large easy to read screen.

Accessories

Whatever it is you're looking for, our accessories range from the gauges and valves in the compressor room, all the way through to the hoses and blow guns at the points of use.

Compressors

Our range of air compressors includes reciprocating piston, oil free, and oil injected rotary screw air compressors, from 3hp up to 660hp, and everything in between. If you do not know what you are looking for, we can assist with that too.

Dryers

Selecting the right dryer and filtration to ensure your facility receives clean, dry compressed air consistently, depends on many things. Our clean air selection process is based around ISO 8573.1 quality class standards.

Filters

If you are looking for assistance in the filtration of dirt, oil, water, bacteria, hydrocarbons, oil odor or vapor, we have a filter, or an element to capture whatever you need to stop. Compressed air, gases, liquids, ambient air, and water filtration is what we do best.

Tanks

Horizontal and Vertical air receiver storage tanks are available, with the most common sizes kept in stock at our Hamilton warehouse.

Condensate Management

Disposing of the compressed air oil/water condensate bi product, created by your compressor station, carries big legal, and environmental responsibilities. The person knowingly discharging oil to drain, is responsible.

N2 and O2 Generators

Reliable Nitrogen Supply, Anytime, Anywhere – Peak i-Flow Nitrogen Generators: Uninterrupted 24/7 operation ensures a consistent, on-demand nitrogen gas flow for various applications, boasting flow rates of up to 11,845 SCFH and purity levels reaching up to 99.9995% (5 PPM).

Pipe Work

Our mechanical team is TSSA certified to perform all types of pipe work, ductwork, plumbing, machinery moving, and rigging.

The ultimate guide on rightsizing your compressed air system

Choosing the right compressed air system is crucial to minimize the total cost of ownership. How do you calculate the air demand in flow rate (CFM) and pressure (PSIG), what's the power requirement (V), and how does that translate in a compressed air system with one or more compressors (hp)?

Download our Comprehensive Guide for Choosing the Right Compressor Size!

Why work with Air Solutions Canada

Working with the largest compressed air team in Southern Ontario has many benefits

Fastest emergency service

With dedicated emergency service breakdown technicians, on call 24/7 we guarantee a same day visit.Every vehicle is equipped with a breakdown “crash kit” to provide us with the best potential opportunity to repair your issue during the first call.

Largest equipment inventory

With $2m of inventory in local warehouses, essential parts, and equipment are readily available. And with more than 50 compressors and dryers in our warehouse we can solve any emergency.

Technicians dedicated to you

We have primary and secondary technicians allocated for each customer, and they have all your information and equipment history on their iPad. It means that we know your particular service history and understand your equipment list.

Competitive Pricing

We get preferential pricing based on our volume purchases, and pass additional discounts on to our customers. We offer payment terms, lease and rent to own options & sell compressed air over the fence, by CFM consumption.