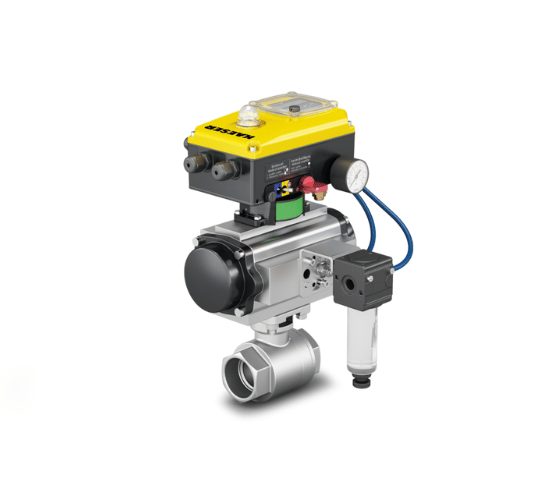

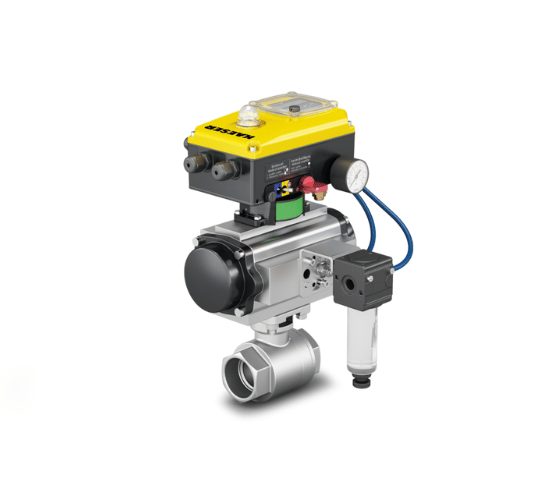

Air Main Charging Valves

Compressed air clean air treatment equipment is designed and rated to perform under specific CFM volumes in specific environments. As an example a fridge dryer achieves a 3°C, (37°F) pressure dew point. Based on an inlet pressure of 100 psig and ambient and approach temperatures of 100°F. Following a system shut down, and repressurization these conditions are seldom achieved and often exceeded, resulting in compressed air contamination carryover. This is particularly prudent at weekends and holidays. Kaeser’s air main charging valve controls the amount of compressed air being allowed to flow into the clean air treatment equipment by modulating open and closed at factory set intervals. In essence the air main charging valve ensures that filters and dryers are able to cope with the influx of compressed air flow and pressure, at any particular temperature following a restart.

Did you find what you were looking for?

The system

The air main charging valve typically sits directly after the clean air treatment equipment, (final stage after filter). The air main charging valve can also be connected to a master control system and is designed specifically to operate in perfect harmony with Kaeser’s Sigma Air Manager (SAM).

Frequently asked questions

What else do Kaeser and Air Solutions Canada offer?

We supply, design, build, and install Kaeser compressors, rotary vacuum, rotary blowers, and a full line of clean air treatments.

Do you offer delivery and pickup services?

Yes, we provide delivery and pickup for all our rental equipment and compressed air solutions, scheduled at your convenience, and typically in our own delivery truck.

How it works

Our tried-and-tested approach to get you a reliable compressed air solution at the lowest possible cost of ownership looks like this:

Discovery call

Our solutions specialist visits your facility to discuss your current situation, pain points, future plans, and potential government incentives. We can undertake as little, or as much, of your project as you would like.

Requirement analysis

We analyze the compressed air equipment at your facility, its performance, condition, control mechanisms, and suitability. We ensure that storage, piping, and compressed air quality are in line with your requirements and best practices.

Turnkey design and installation

Everything we do is “in house.” Compressed air system design, air audits, leak detection, design, build, installation, and air compressor service are handled quickly and efficiently. This approach means that we manage every aspect of your project and create single source supply for you and your organization.

Maintenance and repair

Whether you require emergency breakdown response, predictive, or preventative maintenance our team has you covered. Air end and motor service and rebuilds, piping system, and analysation are also available.