Custom Engineered Solutions

Kaeser's Custom Engineered Solutions are compressed air and vacuum systems built to specification for the most demanding and challenging installations. These complete systems are designed for exceptional reliability, simple maintenance, and superior energy efficiency, no matter what the installation limits may be. They eliminate space, weather, and accessibility constraints and can significantly reduce construction, installation, and operating costs.

Did you find what you were looking for?

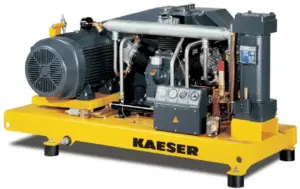

Custom engineered solutions by Kaeser Compressors

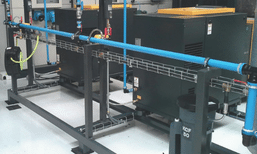

Kaeser's custom air systems are pre-built compressor rooms designed for even the most demanding installations and harshest of environments. These complete systems showcase features common throughout our products: exceptional reliability, simple maintenance, and superior energy efficiency, no matter what the installation limitations may be. Space, weather, and accessibility constraints are eliminated, with reduced construction, installation, and operating costs. Available as skid systems, or containerized compressor system, or a complete customized and engineered system.

The system

Our turnkey approach to custom engineered solutions means that we can design, build, and install whatever your application demands. Compressor stations on portable, skid mounted platforms, sea containers, and weatherproofed buildings are all potential options for your consideration. Many of our custom engineered buildings are installed outside of our customers facilities, to free up desirable and expensive real estate inside their buildings.

Frequently asked questions

What is a Kaeser Compressor?

Kaeser compressors are arguably the most energy efficient, high-quality, industrial-grade air compressors available on the market today. Renowned for their inherent reliability and durability, Kaeser compressors are “built for a lifetime.” Kaeser equipment performances are exceptional, and these can be verified via the compressed air and gas institute.

What types of compressors does Kaeser offer?

Kaeser manufactures a wide range of air compressors, including oil injected rotary screw compressors, reciprocating compressors, and oil free rotary screw machines. Electric and Diesel driven portable, and mobile options, are also available in different sizes and capacities and these can be rented, leased or purchased.

What are the advantages of Kaeser Compressors?

Kaesers patented Sigma profile air ends, produce up to 20% more cfm output volume than competitors equivalents. Exceptionally low noise levels, FIVE YEAR “bumper to bumper” warranty, and long service life, means that Kaeser is the right fit for all types of applications.

How do I select the right Kaeser Compressor for my application?

Selecting the right Kaeser compressor depends on various factors such as your specific application requirements, compressed air demand, operating conditions, available space, and budget. This is where the team at Air Solutions Canada comes in—Canada’s largest Kaeser authorized distributor. Their Compressed Air and Energy Solution Providers will help you determine the most suitable equipment for your needs, taking into consideration factors such as required flow rate, pressure, duty cycle, site conditions, and other specifications.

Are there incentives available for my compressed air project?

We have direct access to government funding, and this is available, at no cost to you, to assist you in updating, or improving your compressed air station and system. In order to benchmark your flow, pressure, and consumption demands, we recommend an Air Demand Analysis, (ADA) study. The results of this study ensure that we select, and engineer the correct equipment, and secure funding towards the project.

How do I maintain a Kaeser Compressor?

Proper maintenance is essential for ensuring the reliable and efficient operation of any compressor. Kaeser provides sensible and affordable maintenance schedules to keep your investment in good running order. Our prime objective is maximum “up time” and peace of mind. Regular maintenance tasks include checking and changing filters, inspecting connections, monitoring oil levels, greasing fittings, cleaning coolers, and performing other routine checks. It's also important to follow any recommended maintenance procedures provided by Kaeser and to use genuine Kaeser parts and lubricants.

Can I get technical support for my Kaeser Compressor?

Yes, Kaeser provides technical support through its authorized distributors. If you encounter any technical issues with your Kaeser compressor, you can contact Air Solutions Canada for assistance, 24 hours a day, 7 days a week. Our service team consists of 16, full-time, Kaeser factory trafactory-trained technicians. We can provide troubleshooting guidance, spare parts, and repair services to keep your compressor running smoothly.

Does Kaeser offer a warranty for their compressors?

Yes, Kaeser offers FIVE YEAR “bumper to bumper” warranty coverage for most compressors. The only stipulations are to complete the startup paperwork, adhere to the manufacturers service guidelines and to use OEM parts and lubricants.

Are there any energy-saving features in Kaeser Compressors?

Yes, Kaeser compressors are known for their energy-efficient design and performance. We produce the most compressed air (CFM), for the least amount of input power, (kW).

With a multitude of operating technologies available, such as Variable Speed Drive, Load/Idle, Modulation, Quatro and Vario to control the compressor, our specific power wins out time and time again compared to others.

Heat recovery, zero compressed air loss drain traps and a master control system option, further improve efficiency, and reduce overall operating costs.

Where can I buy Kaeser Compressors?

Kaeser compressors are available through a global network of authorized distributors and sales partners. Air Solutions Canada is Canada's largest distributor of Kaeser Compressors. We're proud to represent this iconic brand.

How do I know what type of compressed air equipment I need?

Our team of experts can help you determine the right equipment for your specific needs. We'll ask you about your air requirements, the size of your operation, flow, pressure, piping, hoses, power, or fuel, and any specific challenges or constraints you might be facing.

How it works

Our tried-and-tested approach to get you a reliable compressed air solution at the lowest possible cost of ownership looks like this:

Discovery call

Our solutions specialist visits your facility to discuss your current situation, pain points, future plans, and potential government incentives. We can undertake as little, or as much, of your project as you would like.

Requirement analysis

We analyze the compressed air equipment at your facility, its performance, condition, control mechanisms, and suitability. We ensure that storage, piping, and compressed air quality are in line with your requirements and best practices.

Turnkey design and installation

Everything we do is “in house.” Compressed air system design, air audits, leak detection, design, build, installation, and air compressor service are handled quickly and efficiently. This approach means that we manage every aspect of your project and create single source supply for you and your organization.

Maintenance and repair

Whether you require emergency breakdown response, predictive, or preventative maintenance our team has you covered. Air end and motor service and rebuilds, piping system, and analysation are also available.

Related products

Accessories

Whatever it is you're looking for, our accessories range from the gauges and valves in the compressor room, all the way through to the hoses, air knives, nozzles, and blow guns at the points of use.

Blowers

Kaeser blowers are built for a lifetime of high performance, low energy costs, and best in class performance, with flow rates between 170 ICFM and 2603 ICFM.

Vacuums

Kaeser's Rotary screw vacuum packages are the perfect solution to industrial Vacuum applications. Featuring our award-winning Sigma Profile™ airend. Our range of machines produce 166 to 551 acfm.

Boosters

When compressed air or gas applications require higher pressure than a “standard” air compressor can produce, high pressure booster compressors are an economical and effective solution.

Controllers

Kaeser's Sigma air Manager, SAM 4.0 provides complete system management for air compressors, blowers and vacuums, from a large easy to read screen, with remote access options.

Compressors

Our range of air compressors includes reciprocating piston, oil free, and oil injected rotary screw air compressors, from 3hp up to 700hp, and everything in between. If you do not know what you are looking for, we can assist with that too.

Dryers

Selecting the right dryer and filtration to ensure your facility receives clean, dry compressed air consistently, depends on many things. Our clean air selection process is based around ISO 8573.1 quality class standards.

Filters

If you are looking for assistance in the filtration of dirt, oil, water, bacteria, hydrocarbons, oil odor or vapor, we have a filter, or an element to capture unwanted contaminants you need to stop. Compressed air, inert gases, liquids, ambient air, and water filtration is what we do best.

Tanks

Horizontal and Vertical air receiver storage tanks are available, with the most common sizes kept in stock at our Hamilton warehouse.

Condensate Management

Disposing of the compressed air oil/water condensate byproduct, created by your compressor station, carries big legal, and environmental responsibilities. The person knowingly discharging oil to drain, is responsible.

N2 and O2 Generators

Reliable Nitrogen Supply, Anytime, Anywhere – Peak i-Flow Nitrogen Generators: Uninterrupted 24/7 operation ensures a consistent, on-demand nitrogen gas flow for various applications, boasting flow rates of up to 11,845 SCFH and purity levels reaching up to 99.9995% (5 PPM).

Pipe Work

Our mechanical team is TSSA certified to perform all types of pipe work. Stainless steel, copper, aluminum, galvanized and black steel pipe are available for supply and installation. Our team also specializes in ductwork, machinery moving, and rigging applications.