Safety Relief Valves(PRV)

A pressure relief valve (PRV), also known as a safety relief valve or pressure release valve, is a vital safety component utilised in compressor systems, and required by TSSA, to prevent over-pressurization, safeguarding machinery and personnel.

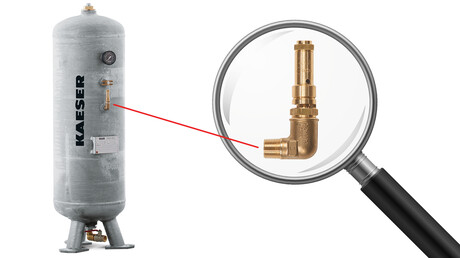

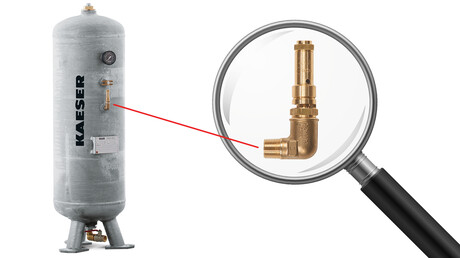

Relief valves counteract over-pressurization by releasing excess pressure. Pressure against the valve seat opens it against spring tension. When pressure surpasses the set threshold, the valve opens, relieving excess pressure. Be sure to direct the discharge orifice of your safety relief valve to a height and an area above, or away from human safety. We recommend that the higher threaded orifices of an air receiver tank are utilised.

Should your safety relief valve discharge it will reseat and close once pressure stabilises averting further over-pressurization.

How to Select Pressure Relief Valves?

Choosing the appropriate valve depends on the specific application. Factors to consider include, the maximum allowable working pressure, (MAWP) of the air receiver tank you’re installing the valve on. The valve must be set to relieve at a pressure which is less than the MAWP of your air receiver tank. As an example if the tank is rated at 165 psig, the safety relief valve will be set at 150 psig. Air Solutions Canada Inc. offers a diverse range of relief valves tailored to various needs, including modular system relief valves, miniature ported valves, and pop-type relief valves, catering to different application demands.

Did you find what you were looking for?

The system

Safety relief valves are installed in all air receiver tank vessels and can be incorporated elsewhere in compressed air distribution systems to safeguard pipework, equipment and of course your personnel.

Frequently asked questions

What else do Kaeser and Air Solutions Canada offer?

We supply, design, build, and install Kaeser compressors, rotary vacuum, rotary blowers, and a full line of clean air treatments.

Do you offer delivery and pickup services?

Yes, we provide delivery and pickup for all our rental equipment and compressed air solutions, scheduled at your convenience, and typically in our own delivery truck.

How it works

Our tried-and-tested approach to get you a reliable compressed air solution at the lowest possible cost of ownership looks like this:

Discovery call

Our solutions specialist visits your facility to discuss your current situation, pain points, future plans, and potential government incentives. We can undertake as little, or as much, of your project as you would like.

Requirement analysis

We analyze the compressed air equipment at your facility, its performance, condition, control mechanisms, and suitability. We ensure that storage, piping, and compressed air quality are in line with your requirements and best practices.

Turnkey design and installation

Everything we do is “in house.” Compressed air system design, air audits, leak detection, design, build, installation, and air compressor service are handled quickly and efficiently. This approach means that we manage every aspect of your project and create single source supply for you and your organization.

Maintenance and repair

Whether you require emergency breakdown response, predictive, or preventative maintenance our team has you covered. Air end and motor service and rebuilds, piping system, and analysation are also available.