Compressed air systems serve as the backbone of numerous industrial operations, providing a safe, reliable, and efficient utility to thousands of industries and applications. Few resources are as versatile and indispensable as compressed air, its widespread use is attributed to its reliability, accessibility, and effectiveness. Whether it's powering pneumatic tools on a production line or providing clean air in critical environments, understanding the fundamentals of compressed air is essential for optimizing performance and realizing the costs associated with owning and operating a system. In this guide, we will delve into the fundamentals of explaining compressed air, its uses, selecting equipment, what each item does, installation tips, and maintenance best practices. Our aim is to provide beginners with a comprehensive understanding of how to make the right choices to optimize efficiency and longevity while maximizing the benefits of a pneumatic system.

What is compressed air?

Compressed air is, simply put, atmospheric air that has been compressed and pressurized for various applications. This pressurization is achieved through air compressors, of which there are several different styles, configurations, and many manufacturers you can consider. More about the types and roles these compressors play later.

Whichever type of compressor you select, it will ingest ambient air and compress it to higher pressures, resulting in a denser, and more energy-rich resource. Compressed air can be stored in air receiver storage tanks, often referred to as reservoirs, or holding tanks. Buyers beware that the ambient air that the air compressor ingests will impact the compressed air that it discharges under pressure. Temperature, hydrocarbons, particulates, and oil will all severely affect the quality and volume that the compressor can produce.

A compressed air system should include all components required to produce, purify, store, and distribute compressed air throughout a facility. In a perfect world, these components include air compressors, air dryers, filtration, storage, piping, flow and pressure controls, condensate management, and well-engineered heating and cooling products. The system's design and configuration depend on the specific requirements of the application, and consulting with a professional will help to ensure that your system is correctly sized, includes all of the necessary components, can be easily serviced, performs to its optimal design capabilities, and is safe and reliable.

Where can I use compressed air?

In most industrial processes, compressed air is used as energy to power things like cylinders, valves, air tools, and paint spray guns. Many applications use compressed air to propel parts, widgets, paint, conveyors, liquids, and products. Brake systems also utilize compressed air on large railway trains, large highway vehicles, such as trucks, and even amusement park rides, like Rollercoasters. Modern-day movie theatres use an air compressor to simulate 4D air movement and the atomization of water too.

Compressed air is extensively used as a breathing air by firefighters, divers, mine workers, and industrial staff who work in confined areas, and hazardous atmospheres.

Why do we use compressed air?

In most industrial processes, compressed air plays a pivotal role in powering equipment and tools, facilitating automation, and ensuring operational efficiency. It is extensively used in manufacturing, construction, automotive, aerospace, and healthcare industries, among others. From powering air tools on production lines to operating pneumatic actuators in robotics, compressed air is indispensable in modern industrial operations. Unlike other energy sources, compressed air is relatively easy to distribute across large areas using piping systems, hoses, valves and cylinders.

At Air Solutions Canada, we strive to promote “best practices” for Everything Compressed Air. We consult, design, select, supply, build, install and service any part or all of a compressed air system, from the generating station all the way to the points of use.

Since 1997, we have been assisting companies across the GTA and Ontario with vast experience to share in all types of applications and industries, and we would love to partner with you. Our competitive differentiators include our ability to manage projects “turnkey”, from the initial consultation, all the way through to after sales service. Nothing is outsourced. We also have direct access to the current Save on Energy incentive rebate program here in Ontario to assist you in funding your projects and improvements.

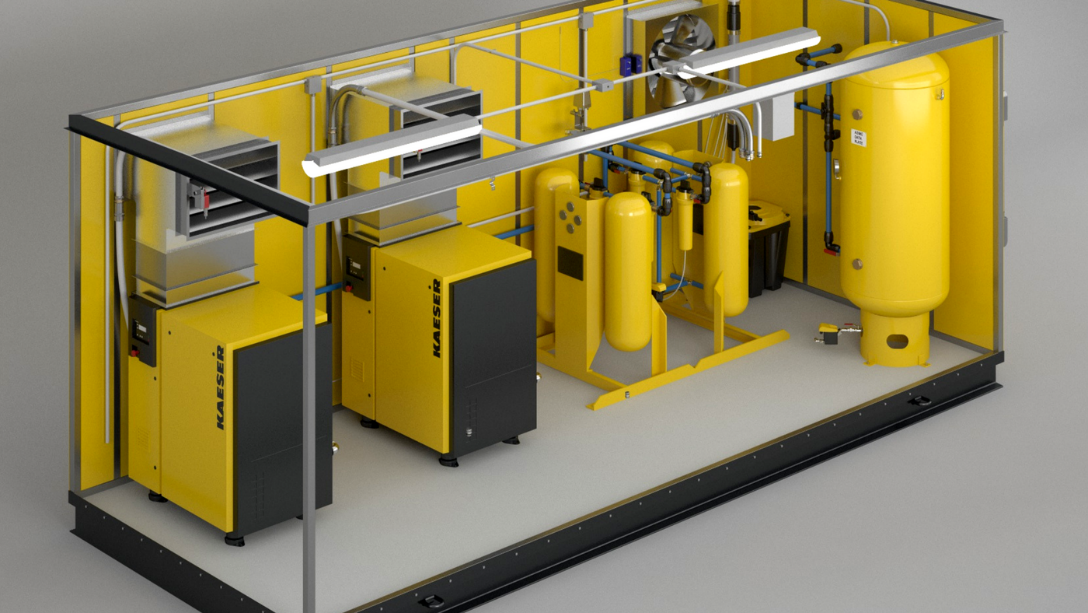

A typical Installation. Lead and Stand 20 hp compressors, Pre- and After-filtration, a Refrigerated Dryer, Zero Loss energy saving condensate drain traps, ample Storage, and Condensate Management treatment.

How to choose the proper compressor for your process

Begin by assessing your specific air requirements, including the volume of air needed, the desired pressure levels, and any special considerations such as air quality requirements. Conducting an energy audit can help identify areas for improvement and guide the selection of equipment and system design with a “right 1st time” approach.

Selecting the right compressor for your application is crucial to ensure efficiency and productivity. Remember that over a 10-year life span of owning an air compressor, only 15% is consumed by capital costs, another 15% on maintenance expenses, AND A WHOPPING 70% on electrical energy costs.

Be sure to size your equipment carefully!

Several types of compressors are available, each with its own set of features, advantages, and benefits. Factors to consider include the required air pressure, flow rate, duty cycle, and environmental conditions. Will you need oil-lubricated or oil-free machines? Will the compressors be cooled by ambient air and a cooling fan, liquid-cooled with water, or a Glycol mix?

Understanding the different types of compressors - such as reciprocating piston, rotary screw, vane and centrifugal—will help in making an informed decision. Let’s look at the options for selecting the correct type of machine.

The most basic air compressor everyone has seen or used is a bicycle pump.

Atmospheric air is sucked into the cylinder as we lengthen the pump, and the atmospheric air we have captured is then compressed in the cylinder to a greater pressure - to create compressed air as the handle is pushed back in the opposite direction. The principle of operation is similar to any type of compressor configuration, but the motion of ingesting ambient air and then compressing it is driven by an electric motor. Entry-level compressors are the popular reciprocating piston compressors commonly used by workshops, tire bays, dental clinics, and roofing contractors. The price point and availability of piston compressors are very affordable and can be delivered quickly. To make the serviceability of a piston compressor accessible, the compressor pump and motor are often mounted on a horizontal storage tank. Horizontal tanks take up large areas of real estate in small shops, so piston compressors are also available on vertical tanks.

Piston compressors can be very noisy and tend to generate unwanted heat. Heat and oil carryover means that compressed air quality is not the greatest either. Be sure to create good ventilation in the room that the compressor resides in, with fresh air louvred intakes at a low level and hot air discharge vents/fans at a high level. Size the filtration and air dryer to match the correct operating conditions you are installing the piston compressor into because both products are typically rated and designed to perform in ambient temps of 100°F, inlet pressure of 100psig, and compressed air approach temps of 100°F.

If these parameters are not met, the performance and capabilities of filters and dryers is severely affected.

Compressed air will typically be discharged from a piston compressor pump at temperatures of 180°C to 200°C, which means, as previously explained, that the air will be too hot for a standard refrigerated-style air dryer and filter to cope with the high discharge and/or ambient temperatures. Using a high approach temperature dryer, which includes an aftercooler is the better solution in cases such as this. Failure to size a purification system correctly will inevitably result in unwanted condensate contamination flooding the system, your tools, points of use and finished products.

Thankfully, Manufacturers such as Kaeser Compressors offer a diverse range of compressor options, including electric-driven rotary screw compressors with onboard after-coolers and dryers included in their packages. These machines are available in different voltages, and pressure specifications, providing users with improved performance, reduced noise levels, and greater energy efficiency, making them ideal for various industrial applications.

Kaeser’s range of compressors. 3hp, to 660hp. Oil Free, and Oil Injected options are available in several different drive variations, such as Variable Speed (SFC), Fixed Speed and Modulation options. Our machines can be cooled by air, or liquid, with multiple pressure and Voltage configurations.

The air compressor “pump” can be oil-lubricated or “dry” (oil-free), depending on the compressed air quality required in your particular application.

It’s important to check and validate the exact specification stated for “oil-free compressed air to avoid spending much more money than you need to invest in producing the compressed air quality needed. Absolute 100% oil-free compressed air is specified, by ISO as being Class 1, as a minimum, but preferably Class 0. However, in our experience, many specifications call for “oil-free” air when in fact, the compressed air quality can be created by an oil-injected rotary screw compressor coupled to correctly sized and graded filters and a desiccant air dryer. The air delivered will be “technically” oil-free with a residual remaining oil level of only 0.003 ppm.

In addition to compressors, air dryers play a crucial role in ensuring the quality of compressed air is acceptable. Dryers are designed to remove moisture and contaminants, ensuring that they meet the required quality standards for all manner of applications. Refrigerated air dryers are commonly used for most indoor applications, providing dew points suitable for most “general” and climate-controlled processes. A pre-filter should protect fridge dryers from particulate and carbon deposit contamination.

Fridge dryers are also designed to purify the CFM flow stated in owner's manuals and brochures, based on a let, ambient temperatures of 100°F, and an inlet pressure of 100psig.

Desiccant dryers may be necessary for applications requiring ultra-dry compressed air and applications operating at temperatures below 37°F (2°C). Desiccant dryers are manufactured in many design formats, with varying regeneration methods. Based on the desiccant fill and purge rate settings, several PDPs can be achieved.

We strongly recommend that you seek professional assistance when selecting a desiccant dryer. The biggest expenses associated with this type of dryer will be the cost of ownership and energy consumption. Our experts would be happy to help you select the best make, style, and model for your application(s).

Air receiver storage tanks are another vital component that is often overlooked when compressed air systems are designed, despite them providing several key features, advantages, and benefits. These include the ability to create cyclonic motion due to the tank's shape, which encourages moisture to condense when air “hits” the tank's internal surface. The subsequent cooling condenses moisture into liquid, and gravity drops this moisture in a coalescing effect towards the bottom of the tank, where an automatic condensate drain trap or manual drain valve removes unwanted oil and water condensate contamination. If your compressor is oil-injected, the condensate should be treated to ensure that only the allowable amounts of oil reach the sanitary sewer.

An example of properly sized storage. As a rule of thumb calculation, plan to include 3 gallons of storage for every 1 CFM of volume your compressor(s) generate.

Do I need compressed air filters?

Filtration is often compromised or forgotten due to budget restrictions or a lack of awareness of the importance of correct purification.

When making your filtration choices, be certain and careful to compare the efficiency at which different manufacturers claim their micron and ppm are captured. These differ massively.

For argument's sake, let's level the playing field and imagine that your filter will be subject to 10,000ppm. If the filter you are considering is rated at 99.9% efficiency for capturing 0.1 ppm of oil, there will be 10 ppm passing this particular filter.

In comparison, an ultrafilter element is rated at 99.99999% efficiency in capturing 0.1ppm, which only leaves 0.001ppm remaining downstream. That's a difference of 9.999ppm of carryover. Can your product, process, or machinery tolerate that much residual oil?

Pre Filters

Pre-filters are designed to combat particulate contamination. By design, most prefilters remove some liquid contamination, be it oil, or water. Particulate removing filter assemblies are typically found on the inlet of a refrigerated air dryer, or the outlet of a desiccant air dryer. Many facilities install point-of-use “general purpose” particulate-removing filters to protect machinery, cylinders and valves.

Element replacement intervals based on 24/7 operation, will be 6 to 12 months, depending on the ambient conditions and air compressor age and regularity of maintenance.

After Filters

To combat liquid oil and water contamination, we now focus our attention on coalescing, oil removing filter assemblies. As with all types of filtration, the efficiency at which they capture dirt oil and liquids is a critical consideration when you select your clean air treatment filters. Coalescing, oil-removing filters are typically found at the outlet of a refrigerated air dryer, at sensitive points of use, and most definitely at the inlet of a desiccant air dryer. The desiccant must always be protected from its “nemesis” - oil contamination. Element replacement intervals are between 6 to 8 months, contingent on the age and condition of your compressor, ambient and operating temperatures, and oil carryover levels.

Final Filters

We are now left with a few remaining “standard” contaminants. These include invisible oil odor and vapor, which can be combatted by an activated carbon stage of filtration. Carbon filter elements and beds will require more frequent filter changes than their upstream counterparts, as they cannot tolerate any form of liquid contamination and their surface area is different from coalescing and depth filters.

Breathable compressed air opens an entirely different can of worms, as we now require the elimination of carbon monoxide (CO), and this is a slightly more challenging method of filtration, which you can investigate and learn more about via our website.

Finally, bacteria may be present in your compressed air lines, which is a major concern in applications where compressed air comes into direct contact with products and packaging.

Bacteria contamination can be eliminated using ultrafilters process range of sterile 0.2 µm P – SRF filtration technology. The P– SRF elements are non-shedding, and capable of withstand 100 steam sterilizations in place. Autoclaving is also another sterilization method to consider.

Condensate Management

An unwanted bi-product of a compressed air system is the oil/water condensate discharge. Because this liquid contains oil, it cannot be sent directly to a sanitary sewer, or a “soak away” area in most plants. If the drains and sewers at your facility are treated on site, you may choose to treat your own compressed air effluent on site, however it’s important to understand that 95% of the oil/water condensate will be water, and only 5% will be oil. Pre-treating the condensate before you send it to your own processing facility usually makes economic sense. Condensate management separators require no electricity and service once per year under normal circumstances.

To ensure that your condensate management separator meets the current municipal limits, let us perform a condensate discharge quality test. It takes 5 minutes and costs nothing. If your system lacks a management separator, we can assist you here as well.

Which compressed air pipe material and configuration do you need?

Choosing the right materials and network layout are essential to ensure that your compressed air generating costs are kept to a minimum and that your operators and machinery receive stable compressed air pressure in sufficient volumes.

To help you make the correct selection, here are a few pointers to consider:

Pipe material. The majority of pipe installations we install today are Blue Aluminum Smart Pipe Plus. This product is powder-coated Blue, so it’s easily identified in the ceiling space as a compressed air pipe. It never corrodes internally and is as light as a feather, so there is no major weight load added to the roof structure. Should you relocate a pipe run or your entire operation in the future, Smart Pipe+ can be disassembled, and everything can be re-purposed in a new location. The flow characteristics and pressure drop of Smart Pipe + are outstanding, compared to standard pipe materials.

Stainless Steel and Copper piping are commonly used in Food, Pharmaceutical, Dairy and Beverage facilities.

Steel, Iron, and Galvanized piping are commonly used in compressed air distribution systems. However, cumulated internal corrosion reduces the internal diameter of the pipe during its service life, which in turn reduces flow, creates friction loss, and, worst of all, increases differential pressure drop and energy costs.

Be sure to invest in the extra piping required to create a loop or a ring main in your network. This will ensure equal pressure is delivered to all areas of the plant. Large headers that dead end eventually manifest into a bigger issue and pressure drops.

How do I maintain my compressed air system?

Proper design, installation, and maintenance are paramount to maximizing the efficiency of a compressed air system.

At Air Solutions Canada, we offer custom-designed preventative maintenance plans, which provide you with peace of mind that a specialist watchdog is taking care of compressed air service for you.

We “cut our cloth” to exactly fit your needs. Our plans are scheduled by service coordinators to keep your system running optimally and limit downtime. They’ll contact you to book the services.