We appreciate that our customers operate on different budgets. Our pre owned equipment program provides excellent alternatives to purchasing new, with peace of mind that the equipment was probably maintained throughout its service life by Air Solutions Canada Inc. Our certified air compressor shop technicians inspect and fully service everything we offer in our pre owned inventory, to ensure that you are purchasing the very best used equipment possible. Our pre owned equipment is supplied to you with varying warranty coverage, depending on the age and condition of the item(s) you are considering.

Kaeser BSD50 Rotary Screw Air Compressor

PreOwned Products

Zander AS325 Desiccant Dryer

PreOwned Products

Kaeser CSD75 - Compressor 2006

PreOwned Products

Kaeser Oil Free Compressor CSG 130-2A

PreOwned Products

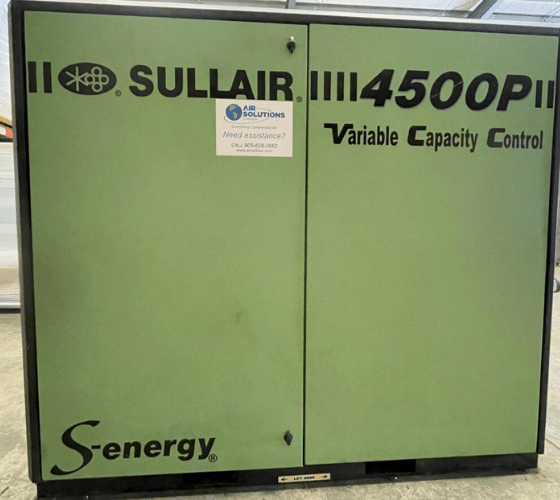

Sullair 4509PS/A Compressor

PreOwned Products

Pioneer PHL500 Desiccant Air Dryer

PreOwned Products

Sullair DHL-250 Desiccant Dryer

PreOwned Products

APPL AP-1200-SP Desiccant Dryer

PreOwned Products

Domnick Hunter BAM Desiccant Dryer

PreOwned Products

Pioneer PHL650 Desiccant Air Dryer

PreOwned Products

Domnick Hunter ES2600 Oil/Water Separator

PreOwned Products

Ingersoll Rand TMS 0380 Refrigerated Air Dryer

PreOwned Products

GRF-500A-536 Refrigerated Air Dryer

PreOwned Products

KADW-25 Desiccant Dryer - DRO588

PreOwned Products

Kaeser KADW 15 Desiccant Dryer DR3700

PreOwned Products

KADW 15 Desiccant Dryer DRO8026

PreOwned Products

Kaeser AS30 30hp Rotary Screw Air Compressor

PreOwned Products

KADW-15 Desiccant Dryer - DRO8098

PreOwned Products

KADW-15 Desiccant Dryer - DR8669

PreOwned Products

Kaeser SFC75 Air Compressor

PreOwned Products

Kaeser TD51 Refrigerated Dryer

PreOwned Products

Kaeser Mobilair Compressor M100

PreOwned Products

Kaeser Mobilair Compressor M250

PreOwned Products

Kaeser AIRTOWER 5C Compressor

PreOwned Products

The ultimate guide on rightsizing your compressed air system

Choosing the right compressed air system is crucial to minimize the total cost of ownership. How do you calculate the air demand in flow rate (CFM) and pressure (PSIG), what's the power requirement (V), and how does that translate in a compressed air system with one or more compressors (hp)?

Download our Comprehensive Guide for Choosing the Right Compressor Size!